Hot melt adhesive is applied on the film, how to choose the film coating machine?

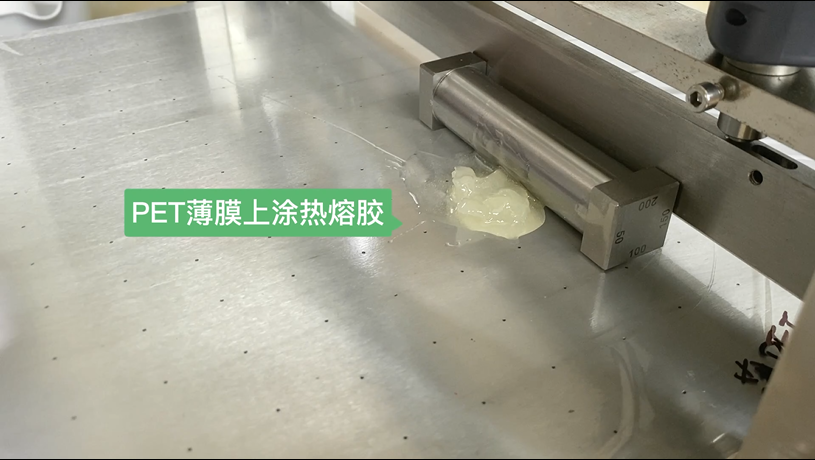

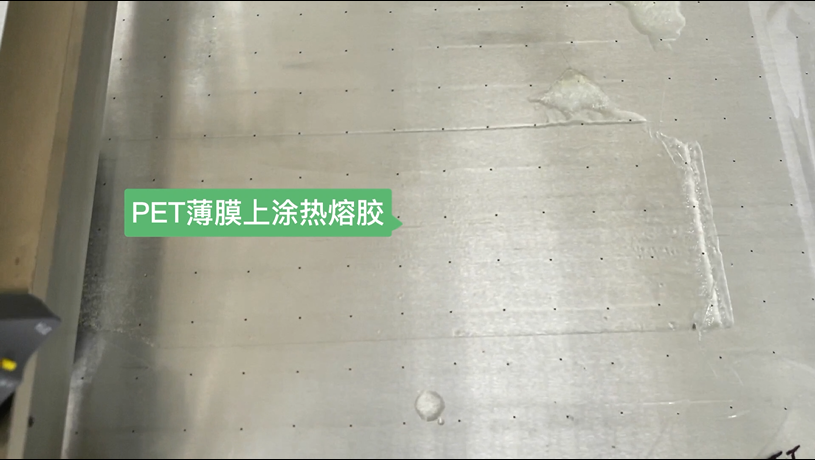

Coating of hot melt adhesive on the film is a relatively common coating type recently. The film itself is relatively thin and soft. During the manual coating process, the coating effect may be affected due to the unevenness of the film and the inability to fix it. At this time, an automatic coating machine is needed for coating. The automatic coating machine can fix the film by vacuum adsorption, and it is designed for this kind of film substrate. The physical state of hot-melt adhesive changes with the change of temperature. During the coating process, it needs to be heated to melt the hot-melt adhesive to continue coating.

Coating of hot melt adhesive on film needs to be tested by using a heated air adsorption coating machine. The following is the test process of this four-in-one coating machine, and the test demonstration screen of hot melt adhesive coating on film.

Note: The general heating temperature of the laboratory coating machine is within 200°C, and the heating temperature should not be set too high. If the temperature is too high, the aluminum plate may be deformed.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body