How to install the wire rod and set the scraping thickness of the scraper in the experimental automatic film coating machine?

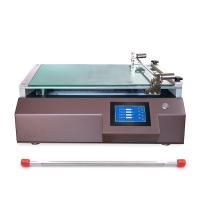

The experimental automatic film coating machine controls the coating film thickness through a wire rod and a scraper. The wire rod coater is more suitable for ultra-thin film, low-viscosity sample scraping and multi-layer coating experiments. It is used in the polymer new material industry. The price comparison is high, and the blade coating is more suitable for thick coating films. The thickness of the blade coating film can reach 10mm. Different brands of automatic film coating machines have different installation methods for wire rods and blade adjustments.

The wire rod installation of the automatic coating machine is mainly to fix the wire rod well, and it is enough not to have rolling during the scraping process to affect the coating effect. Take a look at the specific operation demonstration video below.

The scraper of the laboratory coating machine is adjusted by a micrometer. Remember to put down the coating substrate first and then lower the pressure rod to adjust the micrometer. Take a look at the specific operation demonstration video below.

- 1Application of Mayer Rods in protective coating prepative

- 2NVP anode film FAQ and solution

- 3Application of laboratory coater in LED fluorescent film Spreader

- 4Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 5Application of Automatic Film Applicator in preparing fluorescent diaphragm

- 6Brief analysis of the preparation technology of ionic liquid polymer composite electrolysis and anode pole piece

- 7Application of Mayer Rods in composite coating prepative

- 8Experimental Application and performance Test of Automatic Film Applicator for RTV Silicone Glue on Aluminum Panel

- 9Application Case of Automatic Film Applicator Coating Metal Powder Solution on Titanium Fiber Felt [With Video]