What are the 4 major problems that Automatic Film Applicators mainly solve?

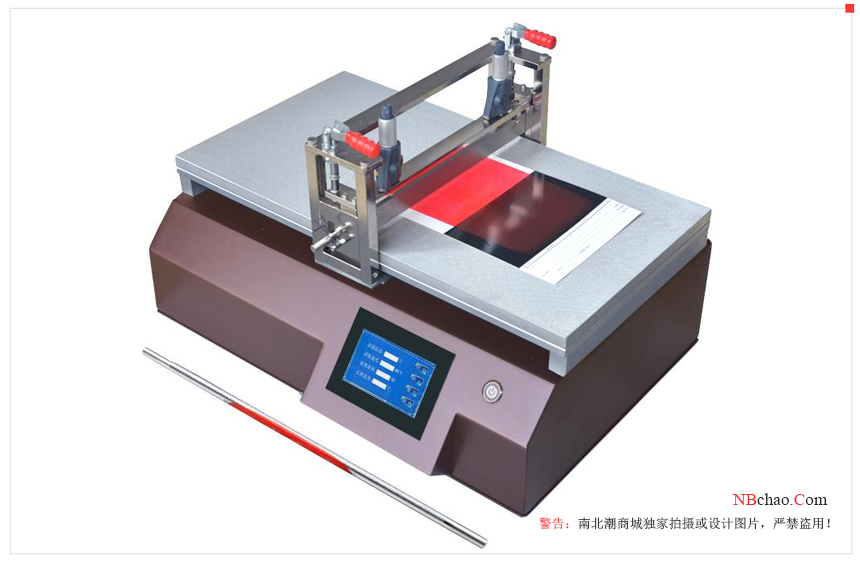

Laboratory Automatic Film Applicator is a Moulding tool that replaces artificial Spreader. Artificial film, force and speed control are different, and sometimes it is difficult to ensure the consistency and accuracy of the film. Automatic Film Applicator can solve the problem of constant speed and constant pressure very well. This paper introduces some problems that are difficult to solve by manual Moulding that Automatic Film Applicator mainly solves.

1. Ultra-thin film

The film thickness of the film mechanism film is not determined by the Automatic Film Applicator, but by the wire rod or Applicator matched on the film machine. Therefore, the precision of the wire rod and the Applicator decisively affects the film accuracy. When preparing ultra-thin films, the precision of the selected wire rod is on the one hand, and on the other hand, the constant speed and constant pressure proofing of the Automatic Film Applicator will also reduce the film error.

2. Thin film substrate film

Since the film substrate is relatively soft and thin, it is difficult to maintain a flat, which will affect the effect of proofing. On the one hand, the film flatness caused by the thin and soft substrate is difficult to fix. On the other hand, the film pressure is difficult to control, and the scraping speed of the material is difficult to control. Uneven, so the vacuum adsorption type Automatic Film Applicator is generally used to ensure the flatness of the film substrate.

3. the film material needs to be heated

Some special materials are solid at room temperature and require a certain temperature to maintain a molten state, such as hot melt adhesives. Hot melt adhesives are materials whose physical state changes with the change of temperature. During the Spreader process, it is necessary to heat them. Let the hot melt adhesive melt down to continue Spreader.

4. multi-layer film

When preparing multi-layer film, substrate material, flatness and bar accuracy, manual control errors, etc. will affect the final proofing result. All multi-layer films have high requirements for manual speed, pressure and flatness. As long as one layer is not well prepared, the subsequent ones are all scrapped, so the Automatic Film Applicator is a good choice.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application of laboratory coater in LED fluorescent film Spreader

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 9Application of Film Applicator in PEM Research and Preparation