Preparation of foam coatings on fabric surfaces with a coating machine

Foam coating finishing is to evenly and completely coat the prepared foam on the surface of the fabric, adhere to the surface of the base fabric after heat treatment and drying, and then improve the performance of the base fabric to obtain a material with excellent performance.

4.2.2.1 Blade coating

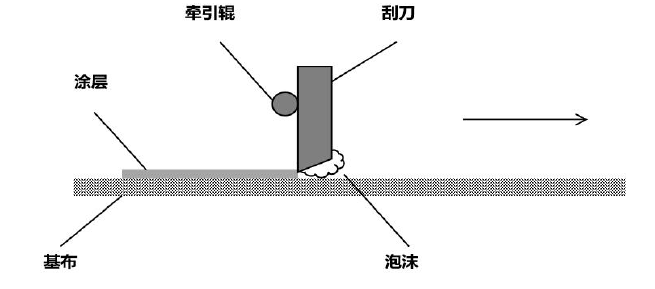

The knife coating method is to use a knife to apply a foaming solution on the surface of the base cloth. Place the scraper directly on the surface of the base cloth, mainly use the downward pressure of the scraper to drive the foam, and scrape the foam onto the surface of the base cloth to complete the coating. As shown in Figure 4-1.

Figure 4-1 Scraper coating device

After the coating is completed on the knife coater, in order to prevent excessive penetration and rupture of the foam and retain the complete foam structure, it is necessary to heat-treat the coated glass fiber cloth immediately. According to the experiments in Chapter 3, it can be known that direct high - temperature treatment of coated glass fiber cloth cannot obtain a good cell structure. The woven fabric is heat treated, expecting to get a good microporous coating structure.

The first stage is low-temperature drying, the drying temperature range is 120-180°C, the purpose is to evaporate the water in the foam coating to obtain a dry coating structure. At this time, the water in the coating evaporates, and the foam coating solidifies on the surface of the glass fiber cloth, which can retain the cell structure for the subsequent formation of a microporous coating structure.

The second stage is high temperature sintering. The sintering range is 330-380°C. The melting point of PTFE is 327°C. Sintering the coated glass fiber cloth near the melting point of PTFE can remove all impurities in the foam coating and PTFE can It remains stable at this temperature without being decomposed, and fusion bonding occurs between PTFE particles to obtain a PTFE microporous structure with certain mechanical properties and dimensional stability.

The third stage is a slow cooling treatment with a temperature range of 360°C-100°C to further optimize the structure . According to the experiments of ChunleiSu et al. [70], after heat-treating the PTFE hollow fiber membrane, the PTFE hollow fiber membrane was placed in a cooling oven, and the heat treatment was continued for 10 hours, and the PTFE hollow fiber membrane with more Better hollow fiber membranes. It shows that heat preservation has a certain positive .

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body