Preparation of fluorescent anti-counterfeiting gravure ink with ink proofing machine

A series of low-content ultraviolet fluorescent gravure inks were obtained by one-step method based on the benzo-free and ketone-free environmentally friendly ink varnish formulations, and their printability and fluorescent properties were studied.

Dissolve 1 part of terbium nitrate hexahydrate in water, add 3 parts of potassium hydroxide and 2,6-dihydroxybenzoic acid deionized aqueous solution, stir at room temperature to obtain white precipitate, filter with suction, wash with a small amount of deionized water , dried to obtain white powder as ink phosphor (hereinafter referred to as phosphor).

Using all-alcohol solvent, four sets of ink formulations were designed by changing the ethanol content . "One-step" preparation process: according to the above formula, accurately weigh self-made fluorescent powder, polyamide resin, erucamide resin, wax powder and ethanol -n-butanol mixed solvent into the ink sample preparation iron tank, add appropriate amount of ink preparation Special glass beads were used, placed in a shaker at room temperature to disperse for 0.5 h, and filtered through a 300-mesh screen to obtain ink samples.

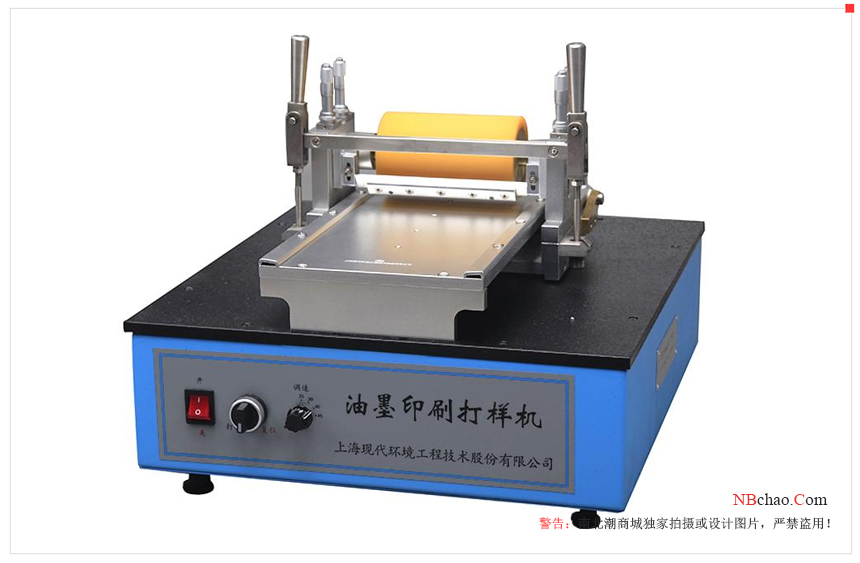

Use RDS18 wire Bar Coater (ink layer thickness is about 41 μm) to prepare printing samples for light resistance and heat resistance, use OSP wire Bar Coater (ink layer thickness is about 15 μm) to prepare phosphor content for light Strong influence Use printing proofs and commercially available inks to print proofs, all of which are scraped on the corona , and the size of the proofs is 25 mm×40 mm. Samples for photography (150 lines, mesh density 100%) were produced using a gravure ink proofer at a speed of 20 m/min.

- 1Application of Manual Ink Proofer

- 2How to calculate flexo ink consumption?

- 3Keep your screen printing customers happy with accurate printing colors

- 4Maintain your screen printing quality with proper screen tension

- 5Preparation of plastic water-based gravure ink by ink proofer

孙伟 - 《北京化工大学》

- 6What faults are prone to photogravure printing? What remedies are there?

- 7The conveying phase of the ink conveying on the printing machine

- 8Distribution phase of ink transport on the printing press

- 9What effect does ink color have on paper?