RCA paper tape testing wear resistance of polyurethane coating for silicone rubber buttons

Compared with ordinary rubber, silicone rubber has both high bond energy and high flexibility, and has excellent heat resistance, aging resistance, low compression and long-term deformation and other unique comprehensive properties and electrical properties. It is widely used in aerospace, aviation, electronic appliances It is widely used in industry and other fields, and its demand is also growing .

The silicone rubber used as a mobile phone, remote control button, and sheath itself has poor wear resistance. Therefore, the surface is often sprayed with a protective coating to increase its wear resistance. Zhang Wei and others used polyurethane prepolymer to modify epoxy resin , and modified epoxy with rigid inorganic fillers, which can improve the acid resistance and abrasion resistance of coatings to varying degrees. Usually, the customer's requirements for the tape abrasion resistance (RCA) of the PU protective coating of the silicone keypad generally range from 500 to 800 cycles . Key protection coatings place higher demands. Compared with the traditional test method, it proposes a test method for ethanol resistance and friction resistance. After 1 hour of ethanol resistance, the RCA test requires more than 400 cycles.

For this reason, this paper mainly investigates the influence of PU chemical structure on the ethanol resistance of the coating , combined with the optimization of matting powder and other additives to further improve the ethanol resistance and friction resistance of the PU coating, so as to improve the service life and meet the needs of foreign customers. Requirements.

Determination of coating wear resistance

Silicone rubber buttons, mobile phone sheaths, etc. are often in contact with hands, and are prone to be stained with sweat. Touching will cause the coating to wear out. Today's commonly used coating wear resistance measurement is not enough to simulate the actual working conditions. For this reason, the new test method of wear resistance requires that before the measurement, the key is immersed in ethanol for 1 hour to measure the wear resistance of the coating.

Coating wear resistance

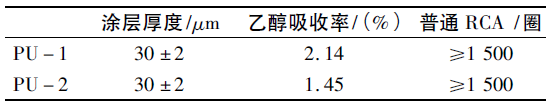

For this reason, this paper selects a typical commercial product PU-1 coating (the number of wear-resisting circles is 1500 circles when not soaked in ethanol ) and the PU-2 coating selected in this paper after adding other additives and ethanol-resistant resin and matting powder. , and the results are shown in the table.

It can be seen that there is no obvious difference in performance between PU-1 and PU-2 in the ordinary RCA test ; while PU-2 has better ethanol resistance than PU-1, so its ethanol resistance RCA test is more excellent, which meets the customer's requirements.

in conclusion

Compared with the existing PU wear-resistant coating, the improved PU coating has improved ethanol resistance, showing better , meeting customer requirements.

- 1Working principle and application of UV coating Cupping testing device

- 2Application of shakeout Tester in organic polymer film abrasion resistance testing

- 3Application of shakeout Tester in aluminum surface coating abrasion resistance testing

- 4Paint film abrasion resistance and test method thereof

- 5Polyethylene (PE) coating indentation hardness inspection and its importance in pipeline corrosion protection

- 6Paint film abrasion resistance and its test method - rubber abrasive wheels method

- 7Determination of abrasion resistance of paint film

- 8Determination method of paint film abrasion resistance and its importance

- 9Coating performance testing: the key to ensuring quality coatings