Application of rca test paper tape in resin for waterborne industrial anti-corrosion baking paint

The development of water-based industrial anti-corrosion baking paint is also a key breakthrough, because the volatility of water is much lower than that of organic solvents, and the water-resistant, anti-penetration and anti-corrosion capabilities of water-based coatings are much lower than oil-based anti-corrosion coatings, so how to choose a good amino-cured water-based resin and the best formula Adaptation must test the patience and ability of the paint designer. In addition, it usually takes time to verify the anti-corrosion ability by using salt spray, but the RCA paper tape friction test can know the performance of the coating film in a short time.

In this experiment, Bayer's water-dilutable resins BAYHYDROLD356, BAYHYDROL PT241, BAYHYDROL A145, and resin A from a European factory were selected, all of which are recommended for water-based baking coatings on outdoor sports equipment. According to the characteristics of different water-based resins to design a reasonable anti-rust primer formula, and test the physical and chemical properties of the coating film after drying, compare the results of the RCA paper tape friction test with the results of the salt spray test to select the appropriate one Resin for water-based industrial anti-corrosion baking paint.

Spraying and drying

(1) Add water to the paint to adjust to a suitable spray viscosity, and paint back and forth 4 times.

(2) Let stand for 10 minutes, and bake according to the recommended baking temperature of the original resin.

Formula E: 120°C, 30 s; Formula F: 150°C, 30 s; Formula J: 120°C, 30 s; Formula H: 150°C, 30 s (the original technical data suggested 120°C, 30 s).

(3) After cooling, perform performance test after 24 hours.

RCA tape test

In this test, the hardness, wear resistance, toughness and other comprehensive properties of the resin can be obtained by using the gravitational abrasion of the paper belt. Generally, RCA is good for coatings with good adhesion, high cross-linking density, high hardness and high film thickness. Such as UV curing resin is an example. According to the RCA test results: E (D356) = H (A145) > J (PT241) > (resin A), this result shows that the cross-linking density of H (A145) is better than other formulations, because its cross-linking density

If the dry film is high, the dry film will be hard and brittle, resulting in poor bending resistance. The reason why the crosslinking density is high lies in the influence of its hydroxyl value on the film properties of hydroxy acrylic paints, see Table 4.

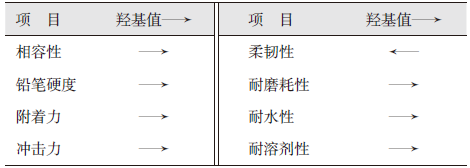

The Effect of Hydroxyl Value on the Properties of Hydroxy Acrylic Coatings

It can be seen from Table 4 that with the increase of the hydroxyl value, other properties except flexibility will be improved. As the hydroxyl content of the hydroxyacrylic resin increases, the crosslinking density of the coating increases, and the number of RCA paper tape tests increases, such as H (A145). D356 of Formula E is a water-based oil-free polyester, its molecules are arranged in a characteristic way, and it has good flexibility, but its high film thickness (30 μm) greatly prevents the RCA paper tape from being worn through to the bottom. Conversely, even though the film thickness of F (resin A) is 30 μm, the number of RCA is the least (80 times). It can be seen that the cross-linking density of the coating film of F is the lowest, and it will not be able to effectively waterproof and penetrate (poor water resistance). It can be predicted that F Will perform worst in salt spray resistance.

- 1How to properly store NORMANTOOL RCA tape in different environments?

- 2RCA paper tape testing wear resistance of polyurethane coating for silicone rubber buttons

朱鹏,刘桃凤,吴绥菊,马海燕 - 《《硅橡胶按键用聚氨酯涂层的性能研究》》

- 3Do you think the difference between genuine and counterfeit RCA paper tapes is just 0.1 coefficient?

- 4Official Instructions for Inconsistent Wear Resistance Coefficient of RCA Test Tape [Translation]

- 5Application of RCA paper tape wear resistance test in wearable equipment decorative film wear resistance test

龚国华 - 《武汉工程大学》

- 6What are the application fields of tape Wear testing machine?

- 7Precautions for RCA tape testing (inconsistent test results)

- 8RCA tape Wear testing machine maintenance method

- 9How to assemble the rca paper tape wear Tester?