How does the Colorimeter test the color difference of cigarette pack printing?

Color difference is an . However, due to the influence of subjective and other factors , it is difficult to accurately judge the color difference by visual inspection alone, and it may also cause objections and disputes between printing companies and customers. Instrument measurement is currently a more popular color difference measurement method. Next, the author will focus on the application of the Colorimeter in cigarette pack printing and share it with readers.

principle

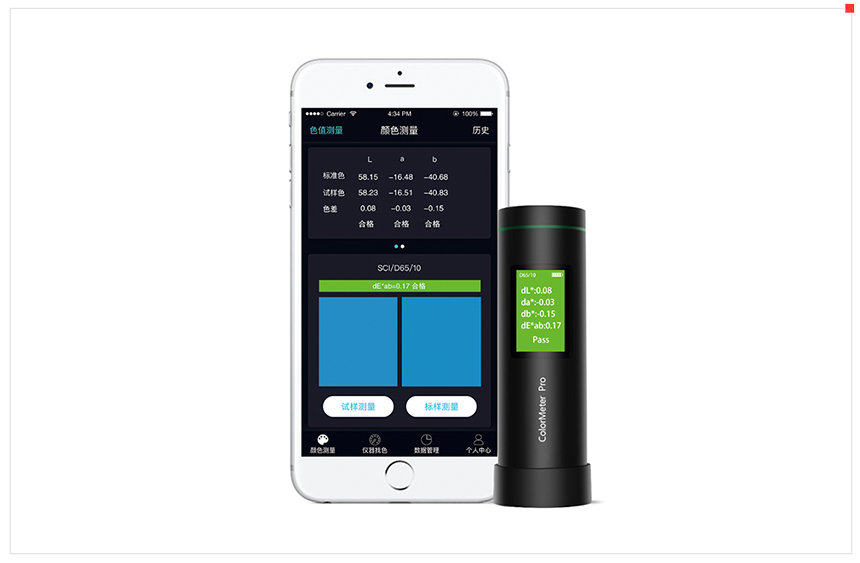

The color difference meter is an optical measuring instrument that simulates the human eye's response to red, green, and blue light. It can analyze the object under test at five angles, and it is customary to choose angles of 15°, 45°, and 110° for analysis. All colors can be perceived and measured by any kind of Lab color scale. The L axis is the brightness axis, 0 is black, and 100 is white; the a axis is the red-green axis, the positive value is red, the negative value is green, and 0 is Neutral color; b-axis is yellow-blue axis, positive value is yellow, negative value is blue, 0 is neutral color. These scales can be used to indicate the color difference between the sample and the standard sample, usually with Δa, Δb, ΔL as identifiers, and ΔE is defined as the total color difference of the sample, but it cannot indicate the shift direction of the color difference of the sample, The larger the ΔE value , the greater the color difference. The color difference meter can measure and display the color difference ΔE and Δa, Δb, ΔL values of the sample and the standard sample according to the Lab and Lch principles of the CIE chromaticity space .

specific measurement method

In actual operation, we mark the measured data as a static coordinate point (called the starting point). In order to ensure the stability of the hue of the printed matter during the printing process , it is necessary for the ink mixer to adjust the ink ratio and viscosity at any time, so that after each adjustment and measurement, other coordinate points can be marked on the coordinate map ( Dilution point, point black point, etc.), there will be a certain movement direction and distance between the two different coordinate points formed before and after each adjustment ( the distance along the coordinate a-axis and b-axis varies, depending on the product Certainly). If we combine this value with the data such as Δa, Δb, ΔL, ΔE displayed on the Colorimeter , it will be displayed as a series of dynamic points on Figure 1 , then the direction and distance between these dynamic points are in actual In the operation, it becomes the qualitative and quantitative reference of which or which color inks and the added amount should be added by the ink mixing workers, which is equivalent to the compass and measuring ruler in the daily ink mixing work .

With such a tool, even new employees can quickly get started in the ink mixing work, and they will not be confused in theory , and old employees will be more comfortable. Of course, in order to achieve such an effect , it is necessary to find out the coordinate points and dynamic points of each product on the coordinate map.

- 1Color difference meter and its application in Coating production

- 2Application of color reader in paper color difference control

- 3Principle, characteristics and application of Spinning & weaving precision color difference instrument

- 4Detection of film color retention with color reader

- 5Optical inspection structure for color readers: D/8 D/0 45 °/0

- 6Application of color reader in inks industry

- 7What is the difference between tristimulus Colorimeter and Colorimeter?

- 8FAQ of computer color reader and its solution

- 9Tristimulus Colorimeter:principle, application, operation and selection