Application of Wear Testing Machine for Wear Resistance Testing of Silk Fibers, Yarns and Fabrics

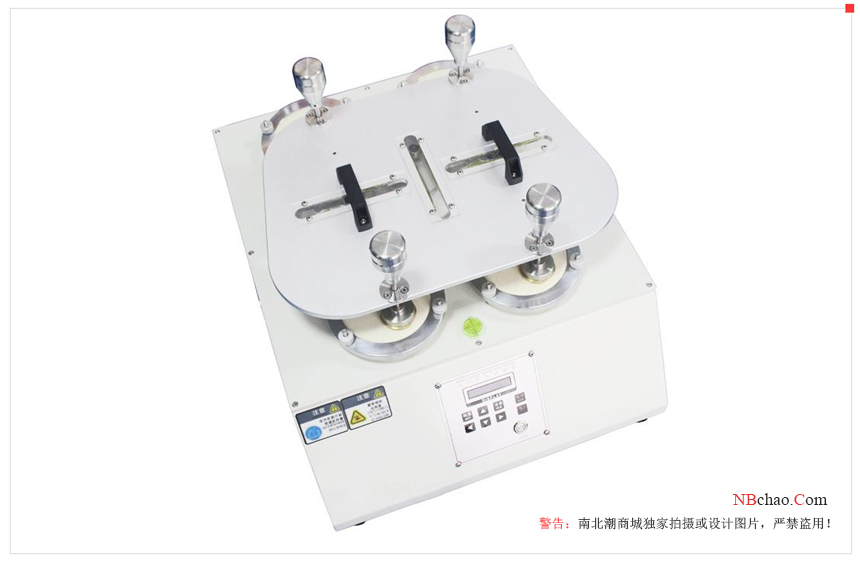

Due to the fine structure of silk filaments, abrasion resistance is an important parameter of silk fabrics. There are many methods for abrasion resistance testing, among which the Martindale Abrasion Tester method (ASTM Standard D4966-12, 2013) [ASTM D4966-12] is a popular method. Abrasion resistance is affected by the test conditions: the nature of the abrasive, the tension on the abrasive, the pressure between the specimen and the abrasive, and the dimensional changes of the specimen. Abrasives were either changed for each sample or kept at a fixed frequency. Wear resistance is measured in number of cycles. It is the number of cycles required to form a pinhole in a specimen or break a set of threads.

Fabric abrasion resistance depends on the true geometric contact area between the fabric surface and the Grinder. For a given force between the fabric and the Grinder, the smaller the contact area, the greater the stress concentration, resulting in reduced fabric abrasion resistance, depending on the number of cycles the fabric tears. Factors that lead to an increased contact area lead to high wear resistance. Plain weaves with unbalanced crimp (the warp yarns are more crimped than the weft yarns) cause the warp crowns to protrude from the surface of the fabric, so the abrader only makes contact with the warp yarns on top of the crimp crowns. A balanced plain weave with the same crimp and yarn size provides more contact area with the Grinder and exhibits higher abrasion resistance. The plain weave of yarns with circular cross-sections (high twist yarns) provides a smaller contact area than yarns with flat cross-sections.

Industrial practice calenders woven fabrics to intentionally increase yarn flatness, surface area, and thus abrasion resistance. An increase in fabric fixation (or cover factor) and/or yarn size results in an increase in contact area and fabric thickness, thereby improving abrasion resistance, provided the balance of warp and weft crimp is not affected. Weaves (other than plain weave) with reasonable float lengths can improve abrasion resistance (fabric fixation (or cover factor) and/or increase in yarn size leads to increased contact area and fabric thickness, which improves abrasion resistance, provided The balance of warp and weft crimp is not affected. Weaves (other than plain weave) with reasonable float lengths can improve abrasion resistance (fabric fixation (or cover factor) and/or increase in yarn size leads to a decrease in contact area and fabric thickness Increased and thus abrasion resistance, provided that the balance of warp and weft crimps is not affected.

Weaves (other than plain weave) with reasonable float lengths can improve abrasion resistance (Backer and Tanenhaus 1951; Seyam and El-Sheikh 1995). However, floats that are too long can cause fluff, which can actually lead to reduced abrasion resistance and negatively affect the appearance of the fabric.

- 1Introduction to common wear resistance test methods

- 2Principle, Application and Selection of Adhesive Tape Wear testing machine

- 3Briefly introduce the working principle, application and selection precautions of rubber Wear testing machine

- 4Basic Principle and Application Analysis of Asphalt Wear testing machine

- 5Basic Principle and Application of Lubricating Oil Wear Resistance Tester

- 6Working principle and application of UV coating Cupping testing device

- 7Application of shakeout Tester in organic polymer film abrasion resistance testing

- 8Application of shakeout Tester in aluminum surface coating abrasion resistance testing

- 9Paint film abrasion resistance and test method thereof