How does the Martindale Wear Tester test and evaluate the wear resistance of fabrics?

Abrasion is an aspect of wear and is the friction of the constituent fibers and yarns of a fabric.

Wear can be divided into the following categories:

Flat or Flat Wear - Flat areas of material are worn away.

Edge fraying - This type of fraying occurs at the collar and folds.

Bending Wear - In this case, friction accompanies bending and flexing

The resistance to damage caused by abrasion of the fabric, known as abrasion resistance.

Factors affecting wear resistance:

Fiber Type:

Nylon is generally considered to have suitable abrasion resistance. Polyester and polypropylene also have good abrasion resistance. It was found that mixing nylon or polyester with wool and cotton increased its abrasion resistance. Viscose and acetate have the lowest abrasion resistance.

Fiber properties:

Fabrics made from longer fibers have better abrasion resistance than short fibers because they are more difficult to remove from the yarn. For the same reason, filament yarns are more abrasive than spun yarns made from the same fibers. Increasing the fiber diameter to the limit increases abrasion resistance.

Yarn twist:

The right amount of twist in the yarn provides the right amount of abrasion resistance. At low twist factors, fibers can be easily removed from the yarn to a progressively smaller diameter. At high twist the fibers are held tighter but the yarn is stiffer so it frays hard under pressure

Fabric Construction:

A fabric with crimps evenly distributed between the warp and weft has suitable abrasion resistance because the damage is evenly distributed between them.

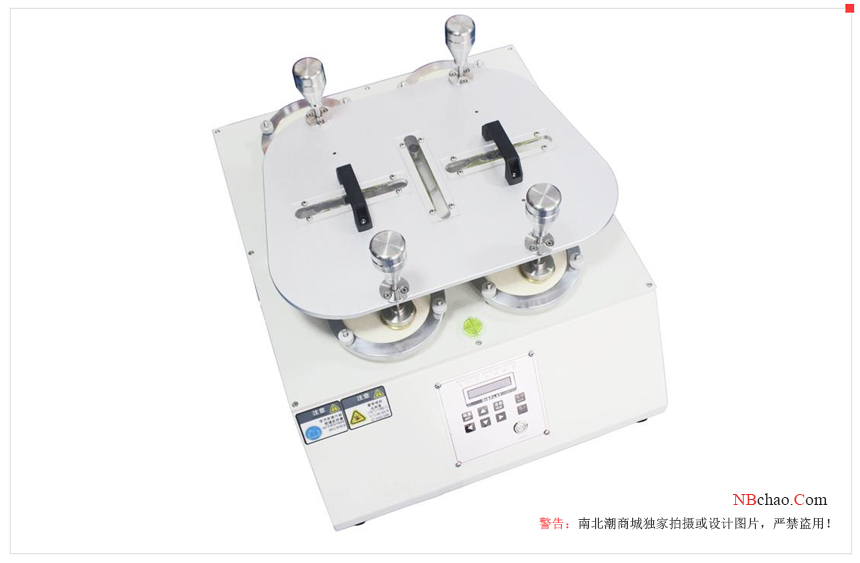

Martindale Abrasion Tester

Machine description:

The device provides a controlled amount of abrasion between fabric surfaces.

Abrasion is imparted in changing directions under relatively low pressure.

In this test, a circular specimen is abraded under a known pressure.

This wear is caused by a motion that is the result of two simple harmonic motions at right angles to each other.

Fabrics are worn against standard fabrics called abrasives.

Abrasion resistance is estimated by visual appearance or loss of specimen mass.

method:

Four specimens, each 38 mm in diameter, were cut using a suitable cutter.

They were then mounted in specimen holders with a circle of standard foam backing behind the fabric. The specimen needs to lie flat on the mounting block.

Place the sample holder with the sample on the abrasive.

The spindle is inserted through the top plate and the correct weight (typically 12kPa pressure, but a lower pressure of 9kPa can be used if specified) is placed on top of it.

The standard wear compound should be replaced at the beginning of each test and after every 50,000 cycles if the test continues beyond this figure.

When replacing the wear agent, use a weight to fix it flat and tighten the fixing ring.

Behind the wear compound, there is a standard backing felt that is replaced every so often.

After the specimen is properly clamped in the grips, apply the desired number of abrasion cycles.

Wear damage assessment:

There are several methods that can be used to determine the extent of damage. Some are mentioned below:

Differences in appearance between worn and unworn specimens.

The number of cycles required to produce holes, broken threads, or broken bars.

Weight loss usually corresponds to the number of cycles. Thickness changes, such as loss of pile height.

Loss of strength, g. Tensile, burst or tear strength, expressed as a percentage of unabrased strength.

Changes in some other properties, such as gloss, breathability, etc.

Microscopic examination of yarn and fiber damage.

Examine the specimen at appropriate intervals without removing it from the holder. In the table, the time interval between checks is shown.

All four specimens should be judged individually. Individual values of the period decomposition for all four samples are reported as well as the mean of these samples.

Points to consider before wear testing / Factors affecting wear testing:

Specimen Condition: Fabrics should be conditioned and tested in a standard test atmosphere.

Selection of test instrumentation: The choice of test instrumentation may depend on the characteristics to be tested, e.g. g-flat wear, flexural wear, etc.

Choice of abrasive motion: Abrasive motion can be reciprocating, rotary or multi-directional.

Wear Direction: The wear direction can be at an angle to the warp and weft directions.

Choice of Abrasive: The severity of wear will vary with the nature of the abrasive. Example: steel and silicon carbide are constantly abrasive. Standard worsted or canvas fabrics, various grades of emery cloth are also used as abrasives.

Supporting Specimens: The hardness of the specimen backing may affect the results. A hard backing is used in some testes and felt or foam rubber in others.

Cleanliness of specimens and instruments: Areas to be abraded should be handled as little as possible and free of foreign matter such as graphite from pencils. Instrument accessories that may rub against fabric need to be spotless and free of grease.

Tension on the specimen: The S-tandem method should be used to mount the specimen to avoid errors due to variations in the tension applied.

Pressure between abrasive and specimen: The severity of wear will be affected by the pressure applied. Therefore, appropriate standards need to be established.

End point of the test: The test should always be stopped once the hole has been appeased or the specimen breaks through the automatic stop motion.

- 1Working principle and application of UV coating Cupping testing device

- 2Application of shakeout Tester in organic polymer film abrasion resistance testing

- 3Application of shakeout Tester in aluminum surface coating abrasion resistance testing

- 4Paint film abrasion resistance and test method thereof

- 5Polyethylene (PE) coating indentation hardness inspection and its importance in pipeline corrosion protection

- 6Paint film abrasion resistance and its test method - rubber abrasive wheels method

- 7Determination of abrasion resistance of paint film

- 8Determination method of paint film abrasion resistance and its importance

- 9Coating performance testing: the key to ensuring quality coatings