What is tear strength? How to test fabric tear strength?

Tear Strength:

When the fabric is grabbed by a sharp object, the fabric tears, and a direct small hole punch translates into a long tear with what may be very little extra effort. This may be a common type of strength failure for fabrics in use. This is especially important in industrial fabrics exposed to rough handling. (such as tents, sacks, parachutes, etc.) In some applications, low tear strength is required, such as tapes, bandages, etc.

Tear strength is the strength required to initiate or continue a tear in a fabric under specified conditions, and tear force is the strength required to continue a tear previously initiated in the fabric. The tear resistance test, or tear strength, is measured on fabrics to check how well a material withstands tearing or cutting under tension. Tear strength is measured according to ASTM D412 standard test method, which is also used to measure tensile and elongation.

The importance of tear strength testing for fabrics:

Tear strength is the resistance of a fabric to tearing. The importance of tear strength for textiles, bulletproof jackets, worker's jeans, tents, garments, sacks and industrial applications cannot be overemphasized. If the tear strength is high, it means that a puncture in the fabric does not propagate easily. The importance of tear strength cannot be overemphasized in industrial textiles, where heavy work is performed.

Factors affecting tear strength are as follows:

The GSM of a fabric indicates tear strength. High GSM means more tear strength.

The strength of the yarn is directly related to the tear strength of the fabric. The higher the yarn strength, the higher the tear strength.

The weave design means that regular weave has the lowest tear strength possible. Also, spun yarns have lower tear strength compared to filament yarns.

Knitted fabrics are less strong than woven fabrics.

Tear strength Testers are suitable tools for measuring the tear resistance of various materials, including textiles and fabrics.

Types of tear tests:

tongue test

Trapezoidal

Elmendorf

Measurement of Fabric Tear Strength:

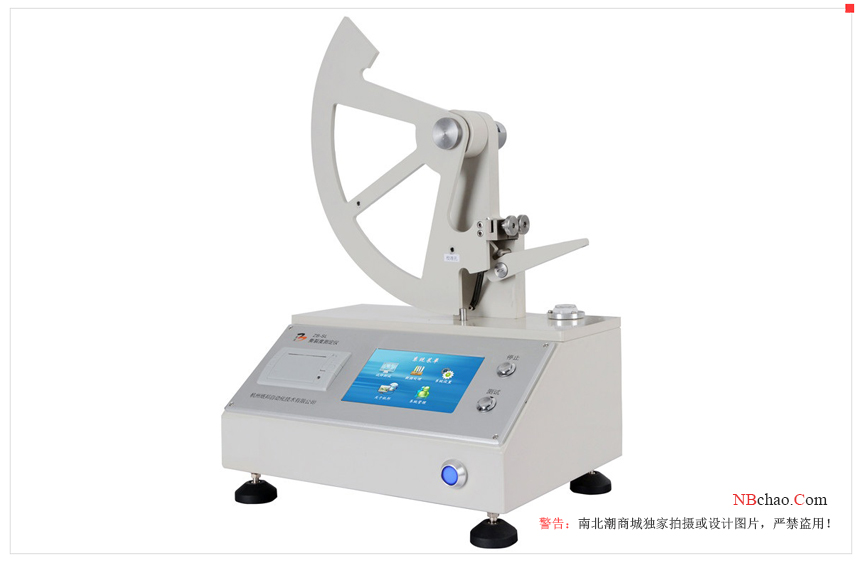

Elmendorf Tear Tester:

Sample Preparation:

First, we take a 100×75 specimen.

Place the template on the specimen and cut according to the template as shown below.

A slit is formed at the middle point of the specimen with an extent of 20 mm.

In the test, Elmendorf continuously tore the fabric from the end of the slit to a distance of 43 mm from the opposite edge.

The pendulum principle is used here.

Work program:

The setup consists of a fan-shaped pendulum with a moving sample holder and fixed clips on the frame.

The specimen is transferred between the two grips while the pendulum is in the raised to home position.

Tear begins at the incision of the specimen between the grips.

The pendulum is then released and the specimen is torn as the moving grip moves away from the stationary grip.

Attached to the pendulum is a pointer that is graduated for direct reading of tear force.

- 1Tear Tester of paper strength

- 2Test method for tensile strength of fabrics

- 3Brech-Imset Double Tear Tester and Edge Tear Tester Test Method

- 4Test method and principle of LW tearing Tester

- 5Elmandorf single tearing meter test method

- 6What is tearing degree? What are the factors that affect tearing degree?

- 7Paper tear Tester operating instructions

- 8What are the common mechanical performance indicators of paper?

- 9Determination of paper tearing - Ellemendorf method