Tips for correctly curing water-based inks

The difference between thermoset inks and water-based inks is especially noticeable when it comes to curing. If you're new to printing with water-based inks, you'll want to learn some curing basics to master the art of creating colorfast water-based prints.

How to cure water-based ink

With plastisol inks, curing simply requires heating the ink to the manufacturer's recommended temperature for a few seconds so that the PVC particles and plasticizer in the ink bond together and hold tightly to the substrate. However, with water-based inks, the ink needs to be held at the curing temperature long enough to evaporate all the water in the ink. Once the water evaporates, the binders and pigments in the ink begin to cure and attach firmly to the fibers in the substrate.

As with any ink, proper curing requires following the ink manufacturer's recommendations. When curing most water-based inks, this means heating the print to 300 to 320 degrees Fahrenheit for 2 to 3 minutes.

Curing Water-Based Inks Using a Conveyor Dryer

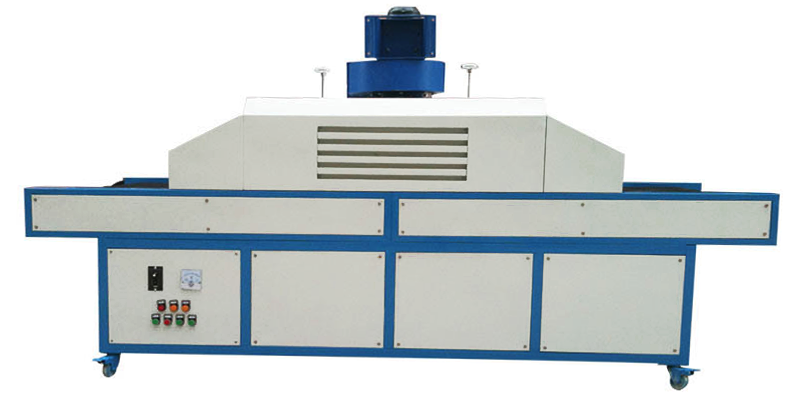

While water-based inks can be cured with a heat gun or flash dryer, most printers recommend curing water-based inks in a conveyor dryer because of the time it takes to dry prints. The challenge with curing water-based inks is heating the ink long enough for it to cure properly without overheating and scorching the substrate. The conveyor dryer is set to a lower temperature and slower conveyor speed to allow for a longer cure time without scorching.

In the 2 to 3 minutes it takes to cure water-based inks, you need to reach a cure temperature of 300 to 320 degrees, so set the conveyor dryer temperature to between 550 and 600 degrees and reduce the conveyor speed. As with curing plastisol inks, you can use a temperature strip or infrared thermometer to check the temperature of the ink as it emerges from the dryer. You'll also want to do a wash test on the trial print to make sure your water-based ink has cured properly.

Additional Considerations for Curing Water-Based Inks

To ensure your water-based ink cures properly, there are a few other considerations to keep in mind.

First, make sure you're not putting too much ink on the substrate. Excess water-based ink won't make your print bolder, because there's only so much ink to hold on to the fibers of your substrate. In addition to wasting ink and money, overuse of water-based inks can lead to longer curing times due to the large amount of water that needs to evaporate from the ink. To use the desired amount of water-based ink, use a mesh screen with a mesh count of approximately 156.

Additionally, when curing water-based inks, the importance of being able to circulate air around the print during the curing process cannot be overemphasized. When water-based ink is heated and cured, water escapes in the form of steam. If the air cannot circulate around the print, the vapor will be trapped and prevent the remaining water from evaporating from the ink.

When curing with a conveyor belt dryer, it is better to use a ventilated conveyor belt dryer to allow air circulation. If you do not have a vented dryer, you should raise the door on the dryer when curing water-based inks to allow steam to escape from the dryer during curing.

Curing water-based inks can seem complicated as it's a different process than curing plastisol inks, but with a little practice you can create water-based prints that are colorfast, just make sure you're not using too much ink and yours is in a well-ventilated area. In the dryer, prints reach the recommended temperature in the recommended time.

- 1Detection performance of water-based ink and its test method

- 26 Benefits of Screen Printing with Water-Based Inks

- 3Performance requirements for UV inks

- 4Types and characteristics of stoving equipment for powder painting

- 5Relationship between water-based ink dispersion and hiding power

- 6Why does the curing process of powder coating need to monitor the furnace temperature?

- 7Coating drying curing