Maintain your screen printing quality with proper screen tension

Improperly tensioned screens will not only reduce the quality of your prints, but also reduce the efficiency of your shop. Fortunately, there are steps you can take to make sure your screen is set up for proper performance.

Put yourself in this situation: You start a print run when you start noticing blurring, smearing, or other imperfections in your prints. Probably the first suspects that come to mind are your artwork and your screen printing press. When you investigate the source of the problem, you'll find that your artwork is set up fine, and your press appears to be functioning properly. What is the culprit of the misprint? Your screen tension might be a less obvious culprit, but it can cause big problems.

How does improper tension affect your prints?

Mesh tension is the degree to which your mesh is stretched in the frame, measured in Newtons per square centimeter (N/cm 2 ). Over time, it becomes more difficult for the screen to return to its original shape due to repeated strikes from the squeegee that can loosen the tension on the screen and deform the screen. An improperly tensioned screen can cause a host of problems:

Improper tension can affect your registration. Even if your production is well set up, your film positives are printed and aligned correctly, and your screen printing press is rock solid, an under-tensioned screen can still produce misaligned prints.

Poor screen tension can affect the integrity of the stencil. On an improperly tensioned screen, the form will break down more quickly due to unnecessary stress on the web. Deteriorated stencils can cause pinholes, blurred edges, and loss of detail in prints.

If your screen is not maintained at the proper tension, your prints may smudge as ink may collect in the folds of the mesh and distribute unevenly.

Screens with lower tension are more likely to pick up ink from the first few layers of a multicolor job because they don't "spring back" into place as they should when the squeegee passes by. Previous ink builds up and blocks the openings of the mesh, preventing subsequent ink layers from passing cleanly through the screen, resulting in blurred prints and loss of detail.

Low tension can make manual screen printing more difficult because you need to use more squeegee pressure to get the ink through the screen.

How do you tell if your screen has the proper tension? You need to know:

A suitable tension is usually between 25 and 35 N/cm 2 , but usually at least 15 N/cm 2 is sufficient. Anything below this value may start to affect your print quality. How do you find these measurements?

How to Find Your Screen Tension

In order to measure your screen tension, you need a device called a tensiometer. It sits on the print side of the screen and detects how much the web is under its weight. When measuring, make sure your screen is on a flat, level surface. Don't measure in just one place - check the entire screen to make sure the tension is even for consistent results. Make sure to measure the tension in both directions - from the top of the screen to the bottom (warp), and from one side of the screen to the other (weft).

Steps you can take to maintain proper tension

What should you do if you find that your screen tension is below 15 N/cm2? If you have the right tools, you can adjust the tension of the screen yourself. A screen tensioner is a device that uses manual or pneumatic grippers to restore the mesh to proper tension. If you don't want to add extra equipment, you can use a retensionable (or roller) frame to make the job easier. If you don't want to do it yourself, there are a few places where you can send your screens to have them re-tensioned.

Remember that your screen tension depends in part on the type of frame you use. Wood framing loses tension over time when exposed to moisture or temperature changes. The adhesive used to secure the mesh to the metal frame degrades over time, causing improper tension. Even roller stands can lose their grip on the mesh over time, so check them regularly to make sure they're maintaining the proper tension and adjust as needed.

When printing, there are a few extra steps you can take to maintain proper screen tension. It's a good idea to use as little non-contact as possible and make sure your screen and tray are level and parallel. This avoids the need to use excessive squeegee pressure, reduces pressure on the screen and allows your squeegee to move faster, increasing your print speed, productivity and efficiency.

One last thing to consider - high screen tension can also be a problem! If your mesh is stretched too tightly, your screen is more likely to be damaged during printing, and if you're using a manual press, it can be more difficult to print.

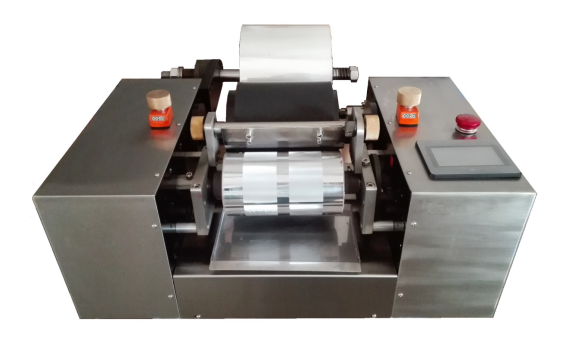

- 1Application of Manual Ink Proofer

- 2How to calculate flexo ink consumption?

- 3Keep your screen printing customers happy with accurate printing colors

- 4Preparation of plastic water-based gravure ink by ink proofer

孙伟 - 《北京化工大学》

- 5Preparation of fluorescent anti-counterfeiting gravure ink with ink proofing machine

向华,龚逸仙,李军,林木雄,欧建志 - 《《用于塑料薄膜的荧光凹印油墨的制备与性能研究》》

- 6What faults are prone to photogravure printing? What remedies are there?

- 7The conveying phase of the ink conveying on the printing machine

- 8Distribution phase of ink transport on the printing press

- 9What effect does ink color have on paper?