How to distinguish the advantages and disadvantages of universal testing machines

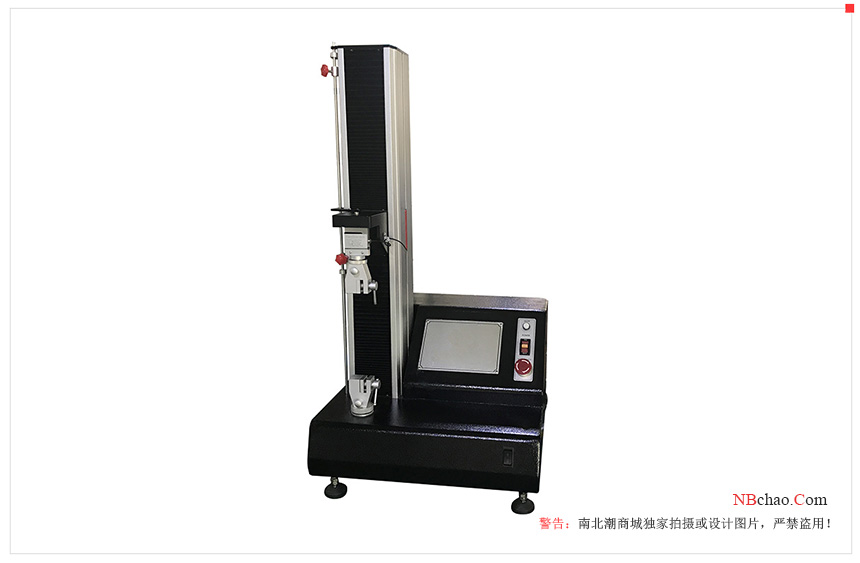

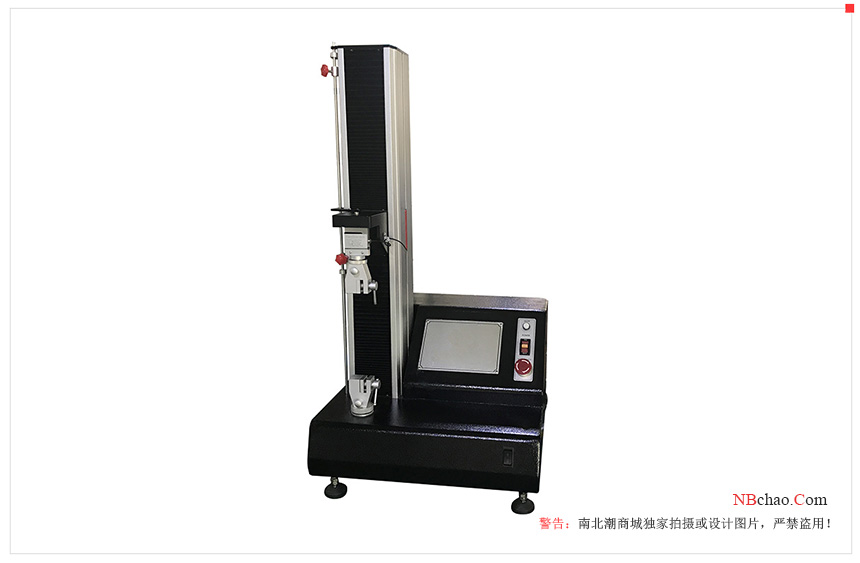

Tensile testing machine is a very versatile testing equipment. It is suitable for testing various physical and mechanical properties of plastic sheets, pipes, profiles, plastic films, rubber, and wires and cables. It is an indispensable testing equipment for material development, physical property testing, teaching research, quality control, etc.

Multipurpose testing machines (UTMs) are reliable workhorses – they can perform hundreds of tests a day, 7 days a week, and maintain the strength required to break specimens under loads of up to 5 kN, 50 kN, and even 600 kN and beyond. generated energy. However, like true workhorses that have been in service for years or decades, they will eventually get old, wear out, and not be as reliable or perform as well as newer replacements

Tensioner fixture is an important part of the instrument. Different materials require different fixtures, which is also an important factor for smooth testing and accurate test results.

advantage

Retains most of the original investment: frame, load cells, accessories

Costs less than new test systems

Considered a maintenance budget item rather than capital equipment in some organizations

shortcoming

Probably not much less than the cost of a new test system, especially for smaller single-column or tabular model frameworks

Costs may not be significantly lower than new systems once service labor becomes a factor

It may not be possible to replace all parts that may fail; if they do fail, the remaining parts may be too expensive or cost prohibitive to replace

- 1Tensile machine application in various industries

- 2Technical analysis of key parameters of Tensile machine: Scientific selection from force measurement accuracy to Power system

- 3Tensile machine purchasing guide [dry version]

- 4Talking about the performance test of epoxy resin film coated on PET

- 5ASTM D5019 Single-layer roofing film reinforced CSM board (chlorosulfonated polyethylene (PE)) standard interpretation

- 6Common problems and solutions in tensile testing

- 7What is tensile strength testing and which products can be tested?

- 8Factors Affecting the Performance and Accuracy of Tensile Testing Machines

- 9Classification of Tensile Testing Machines

-

-

-

CHINA NBC-1024-2 Tensile Tester 5T$ 6635.00

-

-

-