Scratching Polymer Materials on Silicone Mold Applied by Experimental Small Coater

Scraping polymer solution on the silicone mold is a new application case of the NBCHAO experimental coating machine. The thickness of the silicone mold is about one centimeter, and there are grooves of the same size on the mold. The polymer solution needs to be used The wire Bar Coater is scraped onto the silicone mold to scrape out a uniform liquid film. The use of a small coating machine can save manpower, realize automatic coating, and ensure the smoothness of the coating film.

Since the thickness of the silicone mold is relatively large, and the structure is composed of grooves, the scraping process should be gradually added according to the actual situation, so that each grid can be evenly coated with the polymer solution.

The following is a specific experiment demonstration video. Note that the laboratory coater must maintain an appropriate scraping speed during the scraping process.

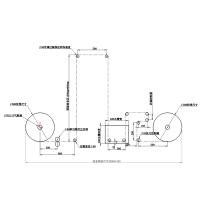

The following is a diagram of the experimental scraping process.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 4Application of doctor blade coater in electrode and solid electrolysis preparation

- 5Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 6Experimental application of water-based paints on film laminating paper by laboratory coater

- 7Experimental coater application case video of liquid silica gel on release paper

- 8Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 9Technical Requirements and Application of Lithium Battery Slurry Coated on Copper Foil for Small Coater