What is the working principle of the dispersion grinding machine?

The all-in-one dispersing and grinding machine integrates the functions of dispersing and grinding in the same machine, which is not only convenient to operate but also reduces waste. So what is its specific working principle?

The dispersing and grinding integrated machine has changed the traditional coating production process, and the two processes of dispersing and grinding are concentrated on one machine , which is simple and convenient to operate, less waste, easy to control the quality, and easy to realize process automation.

The integrated dispersing and grinding machine is used for grinding tiny and very fine solid components in liquid phase. The grinding process is divided into the following 4 steps.

(1) Under the action of the high-speed rotating dispersing disc , the large particle aggregates (powder agglomerates) are broken up to form small particle aggregates.

(2) Stabilize the primary particles, agglomerates and aggregates against reconsolidation .

(3) The grinding basket is lowered to the working position, the material to be ground is sucked into the grinding basket, and the lever on the lever impeller rotates at a high speed to move the grinding beads to refine the material.

(4) The material passes through the dense mesh plate and is discharged from the bottom of the grinding basket.

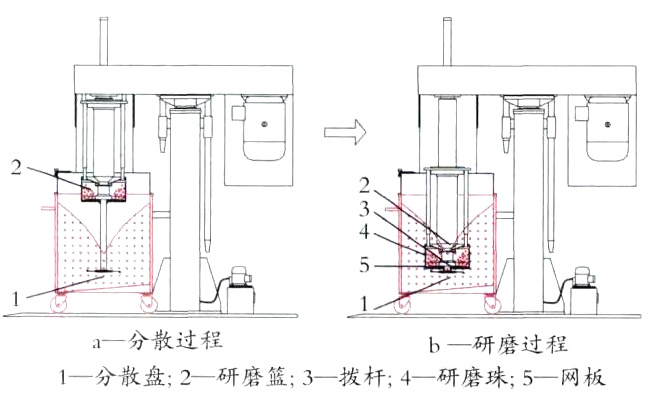

It can be seen from Fig. 2 that during the dispersion process, the dispersion disc 1 is in the working position, and the grinding basket 2 is in the parking position. At this time, the high-speed rotating dispersing disc 1 pre-disperses the materials. During the grinding process, the grinding basket 2 and the dispersing disc 1 are in the working position at the same time, the material to be ground is sucked into the grinding basket, the lever 3 rotates at a high speed, and the grinding beads 4 are driven to grind and refine the material, and then pass through the mesh plate 5. Discharge from the bottom of the grinding basket.

Dispersing and grinding-integrated machine realizes the two processes of dispersing and grinding on one machine and one process, and can also be used as a dispersing machine alone. It can also achieve good grinding effect . The process is simple, less time-consuming, high efficiency, less residue, easy to clean and change colors.

- 1A Brief Discussion on the Difference between Disperser and Stirrer

- 2Several Common Coating Dispersers

- 3Inspection Contents of Chemical Plant Disperser

- 4The difference between Disperser ordinary and explosion-proof type

- 5Laboratory ground Disperser operating procedures

- 6Disperser stirring speed formula

- 7What's wrong with Disperser stirring?

- 8Main Structure of Vacuum Defoaming Disperser

- 9What oil is used in Latex paint Disperser?