Laboratory Coater for Preparation of Silver Nanowire-Graphene Composite Transparent Conductive Films

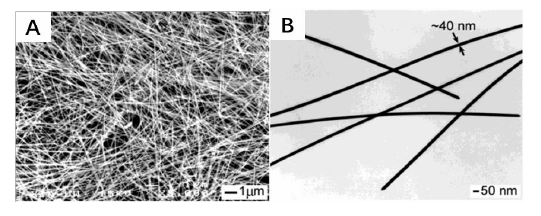

Although silver nanowire transparent films have excellent photoelectric properties and flexibility, there are still many problems in practical applications. For example, nano-silver is prone to oxidation when exposed to the air for a long time, and silver oxide attached to the surface of nano-silver wire will hinder the transmission of electrons and reduce the conductivity of the film, which is the so-called aging phenomenon. In addition, the silver nanowire transparent film is mainly formed by the conductive network between the wires.

At present, many researchers have combined silver nanowires with graphene-based materials, including graphene, graphene oxide (GO), reduced graphene oxide (RGO), etc., which effectively compensates for the application of silver nanowire films in optoelectronics. Some defects of the device.

Preparation of Composite Transparent Conductive Film

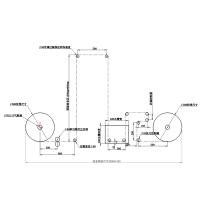

In this chapter, the Meyer bar coating method was used to prepare AgNWs-GO composite transparent conductive films. The Meyer bar coating method is a simple and easy method that can be used to prepare large-scale films. It controls the film formation by setting the rate at which the Meyer rod advances at a certain temperature setting (0-50 C). The Meyer rod used in this experiment is 25 um, which determines the thickness of the wet film. First, cut the roll-shaped PET into a certain shape, absorb a certain amount of conductive ink on the front end of the Meyer rod and start the film coating machine, and the conductive ink will form a layer on the substrate under the push of the Meyer rod. Wet film, after the solvent in the wet film is completely volatilized, a flexible transparent conductive film can be formed on the substrate. In the experiment, the Meyer rod coating method was used to prepare the AgNWs-GO composite transparent conductive film, which was roughly divided into the following two steps:

(1) Pretreatment of the substrate

The substrate used in this experiment is transparent and flexible substrate polyethylene terephthalate (PET). The molecular structure of PET plastic is highly symmetrical and has a certain crystal orientation ability, so it has a high film-forming property. And it has good optical performance and weather resistance, amorphous PET plastic has good optical transparency, PET plastic has excellent wear resistance, friction resistance, dimensional stability and electrical insulation. First, the PET was cut into a certain size. In this paper, three different sizes of 30×30, 15x30 and 7×10 cm2 were selected for the experiment; then the cut PET was washed in deionized water, ethanol and acetone for 15- After 20 minutes, the impurities and organic matter on the surface of the film have been removed; finally, the dried PET is placed in a UV-ozone cleaner with a power of 300 W for 5-10 minutes. The purpose of this step is to hydrophilize the surface of the substrate , to improve the bonding force between the ink and the substrate surface.

(Coating of 2 silver nanowire ink and graphene oxide ink

First, preheat the laboratory film coating machine for 20 minutes, raise it to a temperature of 50 °C and keep it for a certain period of time to make the surface evenly heated, then place a 30×30 cm2 PET on the film coating machine and absorb 1mL of silver nanometer The line ink is dropped on the front end of the Meyer rod, and then the laboratory coater is started to make the ink form a wet film with a thickness of 25 [um on the surface of the PET substrate under the traction of the Meyer rod, and place it at a temperature of 50°C. Let it solidify for 5-10 min, thus forming the AgNW film; then, draw 1mL of graphene oxide ink and drop it on the front end of the Meyer rod, so that it forms on the surface of the AgNW film at a rate of 30 mm s-1 A layer of GO wet film with a thickness of 30 um was placed at 50°C for 5-10 minutes to cure it. Finally, after the solvent in the film was completely evaporated, the AgNWs-GO composite transparent film was formed.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application of laboratory coater in LED fluorescent film Spreader

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research