Preparation of Graphene Oxide Films _ Heating Coating Machine

Graphene oxide GO, as a new type of two-dimensional material, can simultaneously adsorb particulate pollutants and chemical pollutants, and has a certain antibacterial and antibacterial effect, which is unmatched by the materials used in the current air purification technology . Most of the current research on Go in the field of air purification focuses on composite materials, such as mixing graphene as an additive with some organic solvents or loading it on other substances.

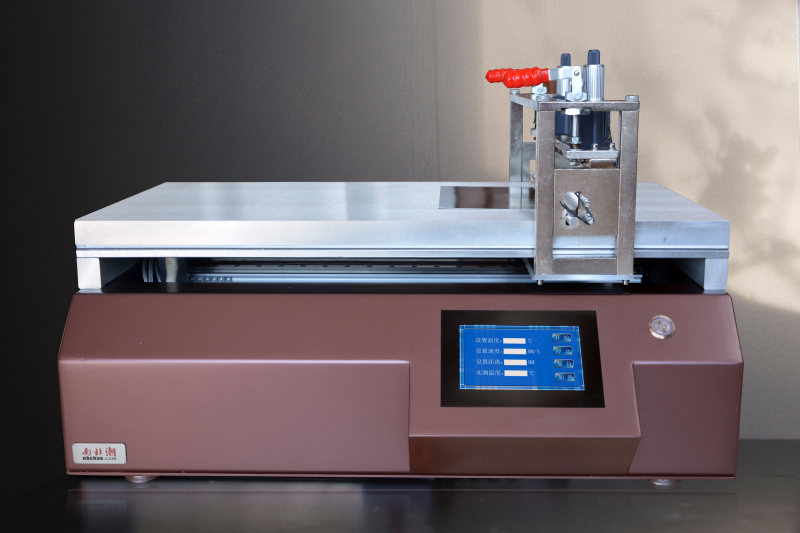

The specific method of preparing graphene oxide film by using experimental heating film coating machine is introduced below.

Go is obtained by the improved Hummers method [62~65]. Go thin films were prepared by scraping and spraying. The preparation of the film is carried out at normal temperature and pressure, and the natural drying humidity is in the range of 40% to 60%.

Disperse the prepared Go solid in deionized water, stir mechanically for 60 minutes at a speed of 500 r/min, and let it stand for 30 minutes to make Go fully wet and swell in deionized water, which is helpful for the next step of dispersion. Followed by ultrasonic (power 1350W, frequency 2000Hz) dispersion treatment for 120min, the temperature of the system should not exceed 20°C during ultrasonication to prevent high temperature from affecting the performance of GО. Go slurries with mass concentrations of 10mg/m1, 20mg/m1, 30mg/m1, 40mg/ml and 50mg/ml were prepared respectively. Using the striped non-woven fabric as the substrate, the Go slurry with different solid content was deposited on the non-woven fabric by drawdown blade coating technology, and the obtained films were PP@10GO, PP@20GO, PP@30GO, PP@40GO and PP@50Go , Non-woven fabric No. PP. The preparation process of GO thin film is shown in Figure 2-1.

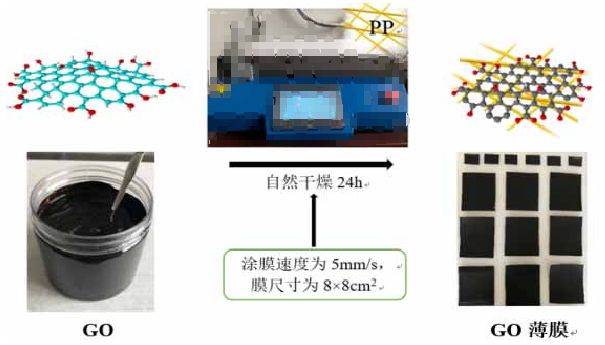

Schematic diagram of preparation of GO film by scraping coating

During the film-making process, the coating film speed was 5mm/s, and the coating film size was 8cm×8cm. The prepared GO film was dried naturally for 24 hours, and the thickness of the nonwoven fabric after drying was 20011um. GO penetrated into the fibers of the nonwoven fabric to form a film, so the thickness of the nonwoven fabric hardly changed. The dried Go films were 1.673g/m2, 3.146g/m2, 4.686g/m2, 6.091g/m2 and 7.296g/m2 respectively.

- 1Drawdown blade Film Applicator Coating UV glue on film

- 2Laboratory Film Applicator for Spreader Chitosan Film

- 3Bar & casting knife heating Film Applicator Application of Water Treatment Film on Non-woven Fabric

- 4Influencing Factors of Glue Coating on PET Film for Small Film Applicators

- 5Selection and Application of Experimental Film Applicator on PET Substrate

- 6Study on Experimental Technique of Automatic Film Applicator for Filtered Glass

- 7Selection and Technical Analysis of Laboratory Film Applicators in Liquid Crystal Dimming Film

- 8Why Do Film Applicators Need to Change Their Wires Regularly?

- 9Experimental Film Applicators: Guidelines for Selection, Operation and Application