Which performance subjects should be tested for waterborne epoxy resin anti-corrosion coatings? How to judge the results?

Water-based epoxy anti-corrosion coatings are coatings that use water as a solvent or dispersion medium. It is suitable for water-based epoxy anti-corrosion coatings on metal substrates, not suitable for water-based epoxy zinc-rich primers. Today we will introduce the regulations of HG/T 4759-2014 on waterborne epoxy resin anticorrosive coatings.

Item detection

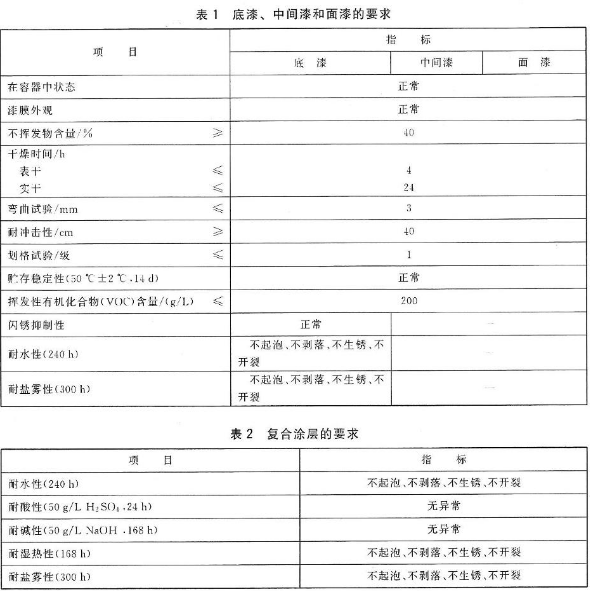

Primer, intermediate and topcoat requirements

1. State in the container: First, we open the container, stir with a spatula or stir bar, and allow precipitation at the bottom of the container. If the primer sample, intermediate paint sample and top coat sample are easy to mix uniformly after stirring, it is rated as "homogeneous and no hard lumps after stirring".

2. Appearance of the paint film: If the paint film of the sample is uniform, without sagging, blooming, cracks, shrinkage cavities, particles, etc., it can be rated as "normal".

3. Non-volatile matter content: the primer sample, intermediate paint and top paint sample ≥ 40%, which is considered to be up to the standard.

4. Drying time: The primer sample, intermediate paint and top coat sample are surface dry ≤ 4h, hard dry ≤ 24h, to be considered up to the standard.

5. Bending test: If the bending parameters of the primer sample, intermediate paint and top paint sample are ≤3mm, it is regarded as up to standard.

6. Impact resistance: If the bending parameters of the primer sample, intermediate paint and top paint sample are ≥ 40cm, it is considered up to the standard.

7. Cross-cut test: test with a cross-cut interval of 1 mm, and the primer sample and topcoat sample are ≤ grade 1, which is considered to be up to standard.

8. Storage stability: put the sample in a constant temperature Drying Oven at 50 ℃ ± 2 ℃, take it out after 14 days, if it is uniform without hard lumps after stirring, it will be rated as "pass".

9. Volatile organic compound content: If the primer sample, intermediate paint and top paint sample are ≤ 200g/L, it is considered to be up to the standard.

10. Flash rust inhibition: If there is no rust on the surface of the primer film sample and no rust spots on the substrate, it is rated as "normal".

11. Water resistance: If the primer sample is immersed in water for 240 hours, and then visually observed under scattered light after the end, if there is no phenomenon such as coating film sickness, it can be rated as "no change".

12. Salt spray resistance: draw a scratch on the test plate parallel to the long side of the test plate for the test. If there are no paint film abnormalities such as blistering, rusting, cracking and peeling, it is rated as "no abnormality".

Composite Coating Requirements

1. Water resistance: Soak the sample in water for 240 hours, take it out and wipe it dry for observation. If 2 of the 3 test panels do not show any abnormalities in the coating film such as blistering, cracking, and peeling, it is rated as "no abnormality".

2. Acid resistance: Immerse the sample in 50g/L H2SO2 solution for 24 days, take it out and wipe it dry for observation. If 2 of the 3 test panels do not have any abnormal coating phenomena such as blistering, cracking, and peeling, it will be rated as "No abnormality".

3. Alkali resistance: Soak the sample in 50g/L NaOH for 168 hours, take it out and wipe it dry for observation. If 2 of the 3 test panels do not show any abnormalities in the coating film such as blistering, cracking, and peeling, it will be rated as "no abnormal".

4. Moisture and heat resistance: place the sample in the test environment for 168 hours, if 2 of the 3 test panels do not show any pathological phenomena such as blistering, cracking, and peeling of the coating film, it will be rated as "no abnormality".

5. Salt spray resistance: draw a scratch parallel to the long side of the test plate on the test plate, and place it for 300h for the test. If there are no paint film abnormalities such as blistering, rusting, cracking and peeling, it is rated as "no abnormality".

- 1Basic Principle and Application Analysis of Paints drying time Tester

- 2Waterborne architectural coatings detection method

- 3Summary of drying time determination method for paint film and putty film

- 4Several Determination Methods of Coating drying time

- 5Paints and varnishes paint film cross-cut test (GB/T 9286)

- 6Coating performance testing: ensuring the efficiency and mass of the painting process

- 7Film drying method: natural drying, heating drying, irradiation curing and gas phase curing

- 8How to detect the drying time of architectural coatings (surface drying)?

- 9How to test architectural coatings workability?