What performance subjects are tested for water-based floor coating materials and how do they meet the standards?

GB/T 22374—2018适用于涂装在水泥砂浆、混凝土等基面上,对地面起装饰、保护作用以及具有特殊功能(防静电性、防滑性等)要求的合成树脂基和聚合物水泥复合地坪涂装材料。今天我们就来介绍一下此标准对水性地坪涂装材料涂层的规定。

在介绍之前我们先要了解它的分类,我们According to地坪涂装材料按其分散介质分为:

S型,水性地坪涂装材料;

W型,无溶剂型地坪涂装材料;

R型,溶剂型地坪涂装材料;

J型,聚合物水泥复合型地坪涂装材料。

再According to成膜机理,将J型分为:

JJ型,有机交联反应型聚合物水泥复合地坪涂装材料,

FJ型,非有机交联反应型聚合物水泥复合地坪涂装材料。

项目检测

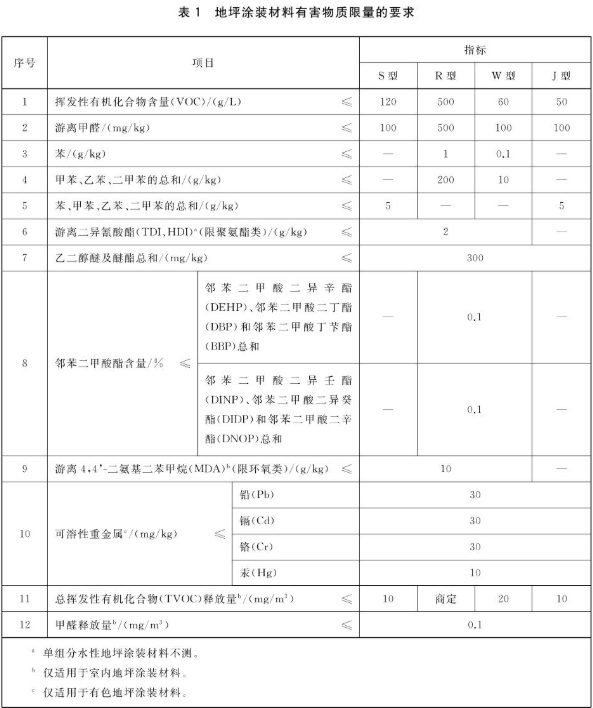

有害物质限量要求

1、挥发性有机化合物含量:S型样品≤120g/L;R型样品≤500g/L;W型样品≤60g/L;J型样品≤50g/L,方算达标。

2、游离甲醛:S型样品≤100mg/kg;R型样品≤500mg/kg;W型样品≤100mg/kg;J型样品≤100mg/kg,方算达标。

3、苯:R型样品≤1g/kg;W型样品≤0.1g/kg,方算达标。

4、甲苯、乙苯、二甲苯的总和:R型样品≤200g/kg;W型样品≤10g/kg,方算达标。

5、苯、甲苯、乙苯、二甲苯的总和:S型样品≤5g/kg;J型样品≤5g/kg,方算达标。

6、游离二异氰酸酯:S、R、W型样品≤2g/kg,方算达标。

7、乙二醇醚及醚脂总和:S、R、W、J型样品≤300mg/kg,方算达标。

8、邻苯二甲酸酯含量

R、W型样品的邻苯二甲酸二异辛酯(DEHP)、邻苯二甲酸二丁酯(DBP)和邻苯二甲酸丁苄酯(BBP)总和含量需≤0.1%,方算达标。

R、W型样品的邻苯二甲酸二异壬酯(DIHP)、邻苯二甲酸二异癸酯(DIDP)和邻苯二甲酸二辛酯(DNOP)总和含量需≤0.1%,方算达标。

9、游离二氨基二苯甲烷:S、R、W型样品≤10g/kg,方算达标。

10、可溶性重金属若样品:若铅(Pb)≤30mg/kg;镉(Cd)≤30mg/kg;铬(Cr)≤30mg/kg;汞(Hg)≤10mg/kg,则算达标。

11. Total volatile organic compounds: If the S-type sample is ≤10mg/m³; the W-type sample is ≤20mg/m³; the J-type sample is ≤10mg/m³, then the standard is met.

12. Formaldehyde emission: If the sample is ≤0.1mg/m³, it is regarded as up to standard.

physical requirements

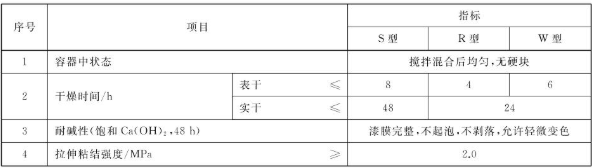

Primer requirements

1. The state in the container: if the S-type, R-type, and W-type are in a uniform state after stirring, and there is no hard lump, it is considered to be up to standard.

2. Drying time: If the surface dryness of S type is ≤8 hours and hard drying ≤48 hours; the surface dryness of R type is ≤4 hours and hard drying ≤24 hours;

3. Alkali resistance: soak the sample in saturated Ca(OH)2 solution for 48 hours, take it out and wipe it dry for observation. If the paint film is intact without blistering and peeling off, and slight discoloration is allowed, it is considered up to the standard.

4. Tensile bond strength: if the sample is ≥2.0MPa, it is considered up to standard.

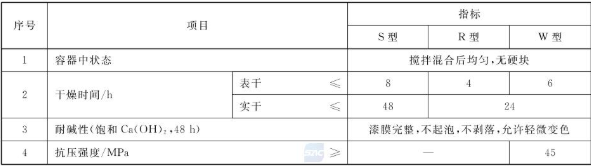

Intermediate coating requirements

1. The state in the container: if the S-type, R-type, and W-type are in a uniform state after stirring, and there is no hard lump, it is considered to be up to standard.

2. Drying time: If the surface dryness of S type is ≤8 hours and hard drying ≤48 hours; the surface dryness of R type is ≤4 hours and hard drying ≤24 hours;

3. Alkali resistance: soak the sample in saturated Ca(OH)2 solution for 48 hours, take it out and wipe it dry for observation. If the paint film is intact without blistering and peeling off, and slight discoloration is allowed, it is considered up to the standard.

4. Tensile bonding strength: If the W-type sample is ≥45MPa, it is considered up to the standard.

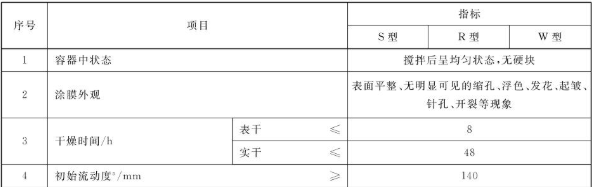

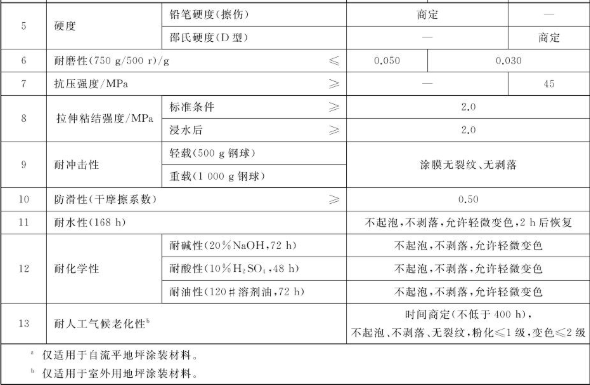

Top coat requirements

Basic performance requirements of water-based, solvent-based and solvent-free floor coating materials, top coats and coating systems

1. The state in the container: if the S-type, R-type, and W-type are in a uniform state after stirring, and there is no hard lump, it is considered to be up to standard.

2. Appearance of the coating film: observe the coating film visually, if the surface is smooth and there is no significant shrinkage cavity, floating color and other coating film pathological phenomena, it is rated as "normal".

3. Drying time: If surface dry ≤ 8h, hard dry ≤ 48h, it is considered up to standard.

4. Initial fluidity: If the sample is ≥140mm, it is regarded as up to standard.

5. Hardness: The reference parameters are determined by both parties of the test according to the actual situation.

6. Abrasion resistance: In the test of 750g/500r, if the S-type sample is ≤0.050g; the W and R-type samples are ≤0.030g, it is regarded as up to standard.

7. Compressive strength: W-type sample ≥ 45MPa, it can be considered up to standard.

8. Tensile bonding strength: ≥2.0MPa under standard conditions; ≥2.0MPa after soaking in water, it is considered to be up to standard.

9. Impact resistance: Under the test requirements of light load 500g steel ball and heavy load 1000g steel ball, if the coating film has no cracks and peeling and other coating film pathological phenomena, it is considered to meet the standard.

10. Anti-slip property: If the coefficient of friction is ≥0.50, it is regarded as up to standard.

11. Water resistance: immersion in water for 168 hours, if there is no abnormal phenomenon of coating film such as blistering and peeling, slight discoloration is allowed, and it recovers after 2 hours, it is considered to meet the standard.

12. Chemical resistance

Alkali resistance: Soak in 20% NaOH solution for 72 hours, if there is no abnormal phenomenon of coating film such as blistering and peeling, and slight discoloration is allowed, it is considered to meet the standard.

Acid resistance: Soak in 10% H2SO4 solution for 48 hours, if there is no abnormal phenomenon of coating film such as blistering and peeling, and slight discoloration is allowed, it is considered to meet the standard.

Oil resistance: soaked in No. 120 solvent oil for 72 hours, if there is no abnormal phenomenon of coating film such as blistering and peeling, and slight discoloration is allowed, it is considered to be up to the standard.

13、耐人工气候老化性:试验时间由双方自行决定但需不低于400h,若结果为无起泡剥落等涂膜病态现象,粉化≤1级,变色≤2级,则算达标。

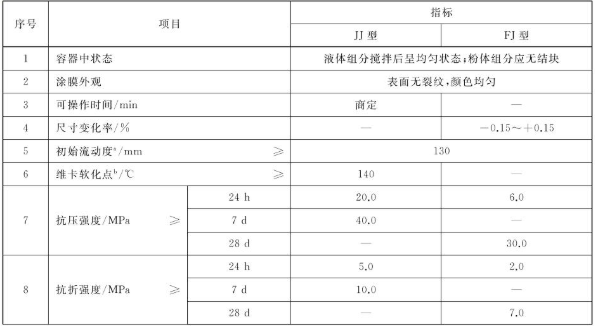

聚合物水泥复合地坪涂装材料面涂的基本性能要求

1、在容器中状态:若JJ型和FJ型搅拌后呈均匀状态,无硬块,则算达标。

2、涂膜外观:目视法观察涂膜,若表面平整,无显著缩孔、浮色等涂膜病态现象,则评定为“正常”。

3、可操作时间:由测验双方按实际情况自行决定参考参数。

4、尺寸变化率:FJ型需在-0.15~+0.15范围内,方算达标。

5、初始流动度:若样品≥130mm,则算达标。

6、维卡软化点:若JJ型样品≥140℃,则算达标。

7、抗压强度:若JJ型样品在24h内≥20.0MPa、7d内≥40.0MPa;FJ型在24h内≥6.0MPa、28d内≥30.0MPa,则算达标。

8、抗折强度:若JJ型样品在24h内≥5.0MPa、7d内≥10.0MPa;FJ型在24h内≥2.0MPa、28d内≥7.0MPa,则算达标。

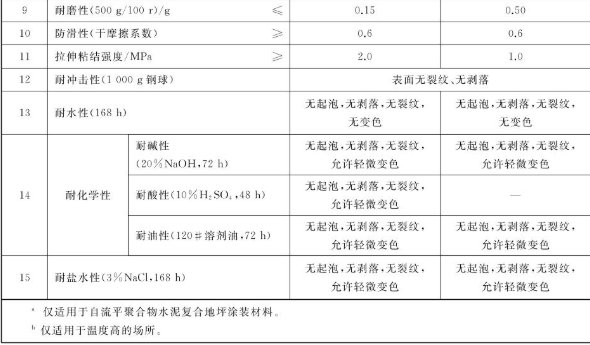

9、耐磨性:在500g/100r的测试中,若JJ型样品≤0.150g;FJ型样品≤0.50g,则算达标。

10、防滑性:若JJ型样品的干摩擦系数≥0.6,FJ型样品的干摩擦系数≥0.6则算达标。

11、拉伸粘结强度:JJ型样品≥2.0MPa;FJ型样品≥1.0MPa,方算达标。

12、耐冲击性:在1000g钢球的测试要求下,若涂膜无裂纹剥落等涂膜病态现象,则算达标。

13、耐水性:浸水168h,若无起泡剥落等涂膜病态现象,则算达标。

14、耐化学性

耐碱性:浸泡在20%的NaOH溶液中72h,若无起泡剥落等涂膜病态现象,允许轻微变色,则算达标。

耐酸性:将JJ型样品浸泡在10%的H2SO4溶液中48h,若无起泡剥落等涂膜病态现象,允许轻微变色,则算达标。

耐油性:浸泡在120号溶剂油中72h,若无起泡剥落等涂膜病态现象,允许轻微变色,则算达标。

15、耐盐水性:浸泡在3%NaCI溶液中168h,若无起泡剥落等涂膜病态现象,允许轻微变色,则算达标。

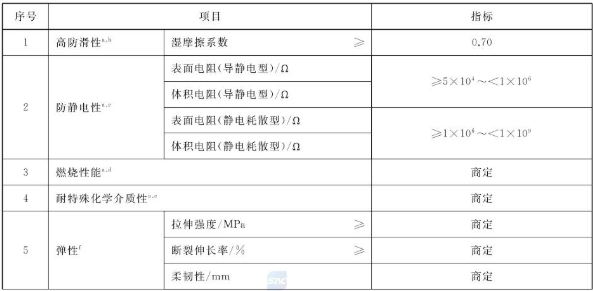

Special performance requirements for top coat or coating system of floor coating materials

1. High skid resistance: wet friction coefficient ≥ 0.70

2. Anti-static property: the surface resistance and volume resistance of the conductive type are ≥5*10^4Ω~1*10^6Ω

3. Combustion performance: The reference parameters are determined by both parties of the test according to the actual situation.

4. Resistance to special chemical media: The reference parameters are determined by both parties of the test according to the actual situation.

5. Elasticity: The reference parameters are determined by both parties of the test according to the actual situation.

- 1Introduction to common wear resistance test methods

- 2Principle, Application and Selection of Adhesive Tape Wear testing machine

- 3Briefly introduce the working principle, application and selection precautions of rubber Wear testing machine

- 4Basic Principle and Application Analysis of Asphalt Wear testing machine

- 5Basic Principle and Application of Lubricating Oil Wear Resistance Tester

- 6Film hardness testing method: pendulum hardness, pencil hardness, etc

- 7Demonstration of RCA wear-resistant tape machine

Air - 《南北潮》

- 8ISO 15184 Pencil method to measure the hardness of paint film

- 9Analysis of hardness measurement by ASTM D3363 pencil method