Solutions for Coating Hot Melt Adhesives on PET Substrates | Small Coaters

This article mainly introduces the solution of coating hot melt adhesive on PET substrate, and uses a small coating machine for experimental scraping.

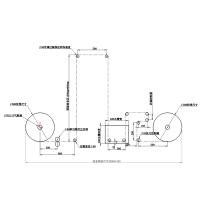

For coating on PET film, because the film substrate is relatively soft and easy to wrinkle, it is often difficult to directly scrape it manually. It is necessary to use the vacuum adsorption function of the experimental small coating machine to keep the substrate flat. However, coating materials with temperature-changing characteristics such as hot-melt adhesives need to be heated to a specified temperature before coating to be in a molten state, so a better solution is to use a base plate heating and adsorption coating machine. Adsorb the PET substrate flatly on the vacuum board, heat the hot melt adhesive to make it flow, and adjust the scraper coating.

The following is a video of the coating experiment of hot melt adhesive on PET substrate. If it is used to coat heated hot melt adhesive, it must first be sure that the melting point of the PET substrate is higher than that of the hot melt adhesive to avoid excessive temperature damage. Substrate. Watch the video below

The following is the vacuum adsorption effect of the film on the film coating machine. Note that the mark in the middle is the crease formed by folding the film for too long.

But what should I do if I want to scrape ultra-thin film or multi-layer film? Consult the North and South Tide technology and exchange professional technical solutions.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 3Application of doctor blade coater in electrode and solid electrolysis preparation

- 4Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 5Experimental application of water-based paints on film laminating paper by laboratory coater

- 6Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 7Technical Requirements and Application of Lithium Battery Slurry Coated on Copper Foil for Small Coater

- 8Application of small coater in gel coating

- 9Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane