Easily fine-tune wet film thickness with a wire rod applicator

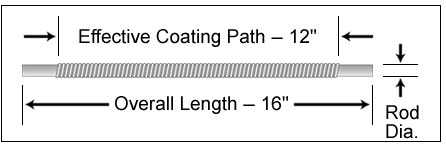

Wire Bar Coaters allow users to quickly and easily fine-tune coating thickness without changing the chemical composition of the coating material or making time-consuming and costly changeovers.

Wet coating thickness can be accurately predicted to within tenths of a mil (0.0001"). Rod selection charts allow coaters to consider coating weight and percent solids when selecting the proper rod size for each production run.

The wire wound rod market has grown rapidly over the past few decades as they provide predictable, accurate coatings time after time at the lowest cost. While the technology dates back nearly a century, today's high-quality materials, multi-wire designs, and special wire surfaces make the system more popular than ever.

In the 1900s, a coater made by Charles Mayer was the first to use a wire-wound rod to make stencil and carbon paper. Many coaters still refer to them as "Mayer Bars".

- 1Application of Mayer Rods in protective coating prepative

- 2Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 3Application of Mayer Rods in composite coating prepative

- 4Several Common Experimental Spreader Methods and Their Applications

- 5Application of Mayer Rods in Water-based ink Moulding

- 6Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 7The experimental case of OSP Mayer Rods at inks Moulding [with video]

- 8Why Do Film Applicators Need to Change Their Wires Regularly?

- 9Mayer-Rod (Mayer Rods) Preparative 2D Copper Nanosheets