Preparation of Polymer Film by PET Substrate Applied by Experimental Coating Machine

This article mainly shares the coating case of the polymer film prepared on the pet substrate, and configures a suitable coating solution according to the experimental requirements.

When choosing the film coating machine directly, Beichao Technology will first understand the specific details of the user's coating film. First of all, what is the substrate of the coating film, and the functions of different substrate configurations are different. PET is a kind of film, obviously The characteristic is that if the substrate is scraped by hand, it is difficult to keep it flat and easy to wrinkle, so it needs to be equipped with vacuum adsorption to maintain its flatness.

Second, what is the sample of the coating film? What is the thickness of the coating film? Polymer glue, the film thickness is about 100 μm, the viscosity is not big. First of all, as glue, the viscosity is very important. For wire rods, it is not suitable for scraping samples with a viscosity above 1000cp, and scratches are easy to appear. At this time, a wet film preparer or a knife coater is required. In addition, the film thickness is relatively thin, such as less than 10 microns, which is relatively thin, so the precision requirements of the optional Applicator must be relatively high. If it is about 100 microns, then the general scraper Applicator can be satisfied.

Finally, whether the sample needs to be heated and dried is to determine whether to configure the heating function, etc.

Based on the above analysis, the coating solution recommended by Beichao Technology is a four-in-one automatic film coating machine or a two-in-one (wire rod adsorption function), and the choice is made according to the actual budget. The details are as follows:

| Membrane Proofing- Membrane | |

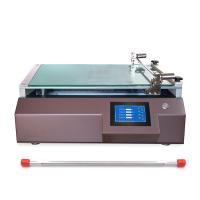

| Domestic TBJ-A3-XB wire rod vacuum adsorption coating testing machine |

| Specification parameters: Coating method wire rod coating, coating base size 300*400mm, coating width 300mm, coating speed 1~200mm/s infinitely variable speed, coating thickness range with 1 domestic wire rod and 1 high precision 1μm imported wire rod, optional film thickness 1.5μm~171.5μm, temperature display accuracy ±2℃, external Vacuum Pump configuration, vacuum adsorption size 300*400mm (customizable), vacuum aperture Φ1.2mm, key control mode touch screen Control, regulator display accuracy ±0.001mm, display digital display, total power consumption 2060W, host power supply 220V 50Hz, overall size 690*410*520mm, machine weight 65Kg, base plate material aluminum alloy, Vacuum Pump size 380*180* 280mm, optional accessories leak tank, substrate fixing fixture, fine-tuning leveling height support leg device, glass plate, silicone pad and weight (for the application of uneven coating substrate thickness), coating film width control baffle, can be Customized function jet system device, UV solid containing device, automatic ink filling system | |

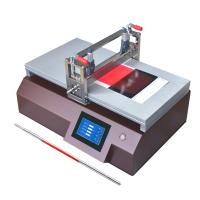

| Domestic TBJ-X3-DJ3 vacuum adsorption wire rod scraper heating integrated coating testing machine |

| Specification parameters: scraper coating accuracy ±0.003mm, coating thickness range 0~10mm, scraper can be raised and lowered, coating rate 2~200mm/s, coating format 300*500mm (coating length 0-400mm can be set arbitrarily), coating Speed digital display, different speeds, vacuum adsorption size 300*500mm (customizable), vacuum hole diameter Φ1.2mm, vacuum hole distance 20*20mm, scraper length, coating rod specification 1 domestic wire rod + 1 rod, the accuracy is as high as 1μm imported wire rod, effective coating width 300mm (determined coating thickness according to the type of wire rod), host power supply 220V 50HZ, external dimension 722*480*450mm, net weight 65KG, speed control infinitely variable speed, base plate material aluminum alloy, heating Temperature range RT+~200°C, temperature uniformity temperature ±3°C, power 1500W, Vacuum Pump size 380*180*280mm, optional accessories leakage tank, substrate fixing fixture, fine-tuning leveling height support leg device, glass plate, silicone pad And weights (for the application of uneven thickness of coating substrates), coating film width control baffle, customizable functional jet system device, UV solid containing device, automatic ink filling system | |

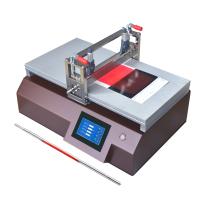

| Domestic TBJ-X3-XB vacuum adsorption wire rod scraper heating integrated coating testing machine |

| Specification parameters: scraper coating accuracy ±0.003mm, coating thickness range 0~10mm scraper can be raised and lowered, coating rate 2~200mm/s, coating width 300*400mm (coating length 0-400mm can be set arbitrarily), coating Speed digital display, different speeds, vacuum adsorption size 300*400mm (customizable), vacuum hole diameter Φ1.2mm, vacuum hole distance 20*20mm, scraper length, coating rod specification 1 domestic wire rod + 1 rod, the accuracy is as high as 1μm imported wire rod, effective coating width 300mm (coating thickness is determined according to the type of wire rod), host power supply 220V 50HZ, external dimension 630*410*520mm, net weight 65KG, speed control infinitely variable speed, base plate material aluminum alloy, heating Temperature range RT+~200°C, temperature uniformity temperature ±3°C, power 1500W, Vacuum Pump size 380*180*280mm, optional accessories leakage tank, substrate fixing fixture, fine-tuning leveling height support leg device, glass plate, silicone pad And weights (for the application of uneven thickness of coating substrates), coating film width control baffle, customizable functional jet system device, UV solid containing device, automatic ink filling system | |

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application of laboratory coater in LED fluorescent film Spreader

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research