Case | Laboratory Automatic Film Applicator for PET Coating Silicone

Which Automatic Film Applicator to choose for silicone coating on PET film? Another user came to consult nbchao technology. Moulding proofing on PET film is a very common application of Automatic Film Applicator in the laboratory, especially the rapid development of New materials, PET film Moulding to improve product performance in different industries. Without further ado, go straight to the topic.

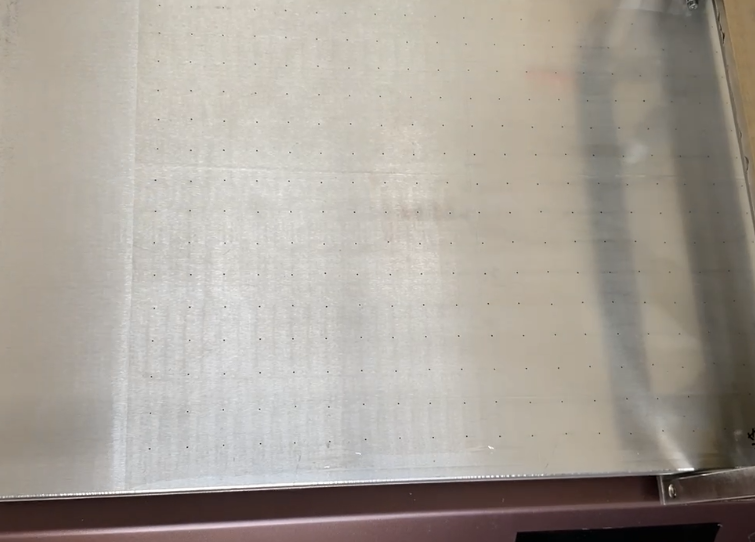

PET film as a soft and easily wrinkled substrate, if the use of manual film, is often a variety of rollover site, for the film substrate, Automatic Film Applicator vacuum adsorption function is very important, through vacuum adsorption, can be very fast substrate adsorption flat, improve the uniformity of the film.

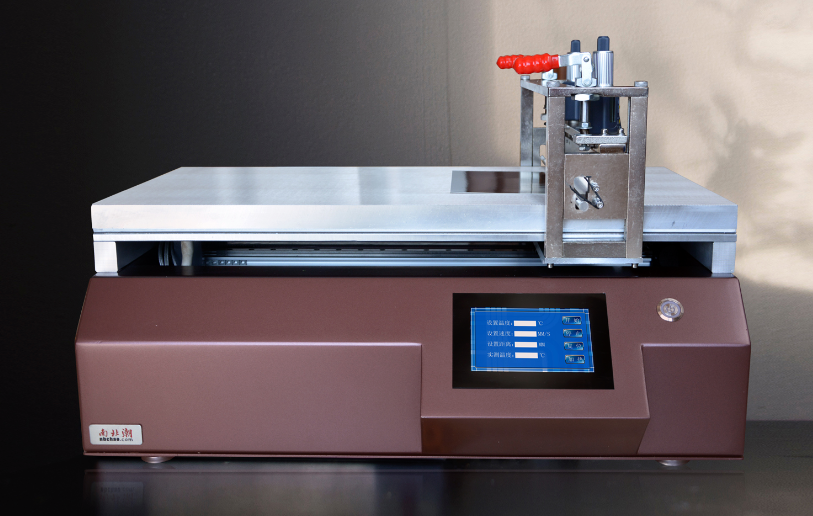

Silicone is an organic silicon compound, commonly used as sealant, gluing agent, lubricant, etc., which is widely used in electronics, furniture, electrical appliances, automobiles and other industries. This selection case is mainly to scrape and coat a silicon film with a thickness of 200-300 μm. The film thickness is relatively thick, and it can be directly scraped with an adjustable scraper-type Spreader.

In view of the occasional need of users to scratch film and heat and dry samples, the technology recommends a four-in-one experimental Automatic Film Applicator. The following Automatic Film Applicators are for reference, please consult nbchao technology for details.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research