How to test viscosity?

Many instruments are available. Rheometers are capable of passing a wide range of shear stresses. The plastic trim industry typically uses much simpler equipment. As mentioned, perhaps a common device is the Rotational Viscometer, where the motor is coupled to the submerged spindle via a tensiometer. The spindle rotates in the liquid to be measured. The higher the viscosity (resistance to flow), the higher the reading on the tensiometer. There are several spindle diameters to choose from and a wide range of rotational speeds to choose from. Viscosity needs to be reported along with spindle size, RPM and temperature.

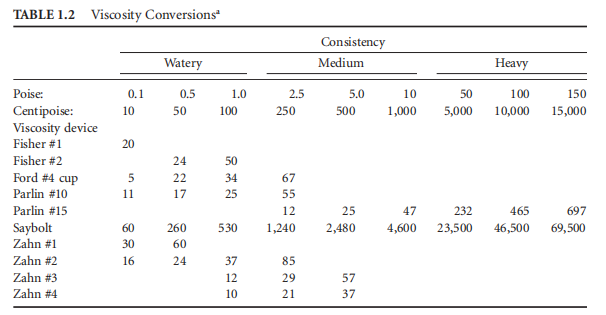

The liquid temperature is 25°C. For liquids with a specific gravity of approximately 1.0, values are in seconds.

A Rotational Viscometer is an excellent tool for quality control. While certainly not a replacement for a rheometer, a viscometer can be used to estimate the change in viscosity with shear. Viscosity readings are taken at different rotational speeds and compared. Highly thixotropic materials will be easily identified.

A simpler viscosity device is the Flow Cup, a simple container with an opening at the bottom. Ford cups and Zan cups are very common in the field of plastic painting. The Ford Cup is the more accurate of the two cups and is supported on a stand. After filling, open the bottom hole and record the time for the liquid to flow out. Unlike a Rotational Viscometer, which produces a centipoise value, the cup only gives the flow time. Relative flow times reflect different relative viscosities. A conversion chart allows conversion of Ford and other cup values to centipoise (Table 1.2).

The Zahn cup is dipped into the liquid sample through its handle and withdrawn quickly, so the empty time is recorded. Zahn type equipment is commonly used in-line equipment, mainly as inspection equipment for familiar materials.

-

-

TQCsheen VF2199 Lory Viscosity Cup$ 457.00

- 1Rotational viscometer - principle, classification, application and calibrating

- 2Application of NDJ-8S digital Rotational Viscometer in viscosity measurement of cosmetic raw materials

- 3NDJ-5S digital Rotational Viscometer accurate measurement of natural oil viscosity

- 4Viscosity of polypropylene (PP) amide measured by NDJ Viscometer

- 5Application of HBDV-1H swirl/spin High Temperature Viscometer in Viscosity Determination of Plastic Particles

- 6Rotational viscometer selection guide: How to choose the right viscosity equipment for you?

- 7Principle, type and accuracy control of Rotational Viscometer

- 8Which Viscometer to Choose for Licorice Extract Viscosity Testing? How to Test?

- 9Application of Rotational viscometer in Waterborne Polyurethane Adhesive