What is leveling? What parameters affect leveling?

Leveling depends on rheology and surface chemistry. This is a more complex and less controllable phenomenon. Coatings applied by spraying, dipping, rolling and most other methods are often not smooth enough to be aesthetically appealing. Splashes, streamlines, ridges, and other topological defects require liquid materials to be flat. Therefore, it is important to understand the dynamics of leveling.

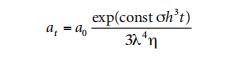

We will first assume that proper wetting has been achieved, using a wetting agent if necessary. Important parameters affecting leveling are viscosity, surface tension, yield value, coating thickness and wet coating irregularity. Some workers have developed empirical relations to describe levels. The leveling equation (equation 1.4) is very useful.

at = amplitude (height) of the coating ridge

σ = surface tension of the coating

η = coating viscosity

h = coating thickness or height

t = leveling time

λ = wavelength or distance between ridges

Equation 1.4 shows that flatness is improved by one or more of the following:

1. Longer time (t)

2. Higher coating surface tension (σ)

3. Lower viscosity (η)

4. Larger coating thickness (h)

5. Small repetition distance between ridges (λ)

Note that the coating thickness h is cubic. Doubling the thickness provides an eight-fold (23) improvement in flatness. Note also that the wavelength λ between ridges is raised to the fourth power. This means that ridges that are far apart create very difficult leveling situations.

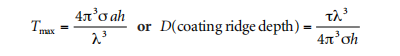

Earlier, it was pointed out that a high yield value might prevent leveling. The shear stress on the wet coating needs to be greater than the yield value to produce leveling. Equation 1.5 shows the relationship between various parameters and shear stress.

σ = surface tension of the coating

a = amplitude of coating ridge

h = coating height

λ = coating ridge wavelength

Since Equation 1.5 deals with forces, the time factor and viscosity values drop. It can be seen that increasing the surface tension and coating thickness produces the greatest shear stress. Coating defect height (a) increases shear, while wavelength (λ) greatly reduces it. If coating bulging cannot be avoided, a higher, tighter coating bulge is recommended.

Leveling does not occur when the yield value is above the maximum shear (Tmax). Extending the leveling time and reducing the viscosity will not help overcome the yield value barrier because these terms are not in the shear equation. Increasing surface tension and coating thickness is optional, but there are practical limits.

Since yield value is often affected by shear (thixotropy), coating application rate and premixing conditions can be important. Higher roll speeds (for roll coaters) and higher spray pressures (for Spray Guns) will temporarily reduce the yield value. It is obvious that the lowest surface tension cannot achieve good leveling. Higher surface tension promotes leveling, although good wetting may require lower surface tension. This is another reason to use the lowest effective level of surfactant.

- 1Types, applications and evaluation methods of levelling agents

- 2Working mechanism and selection considerations of anti-shrinkage agent

- 3Coating performance testing: leveling & sagging

- 4Coating surface tension and its effects

- 5Coating leveling and sagging

- 6Key Factors and Evaluation Methods of Coating Constructability

- 7Coating performance testing: ensuring the efficiency and mass of the painting process

- 8Coating levelling and sagging performance test

- 9what is the coating Leveling and Sag resistance