Influence of Leveling on Rheological Phenomena of Coatings

Leveling is a critical step in achieving a smooth and uniform coating. During the application of the coating, defects such as waves or wrinkles often appear on the surface. For the coating to be acceptable, these defects need to disappear before the wet coating (fluid) solidifies.

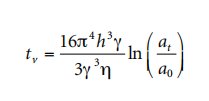

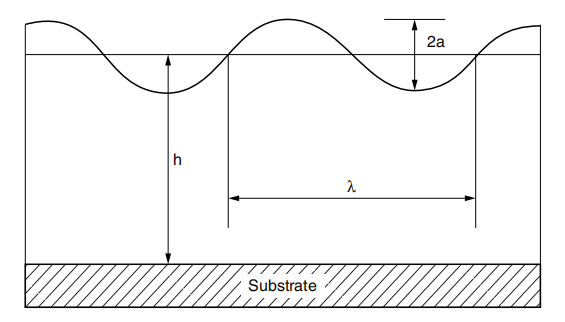

Surface tension has been generally recognized as the primary driver of coating flow, while resistance to flow is the coating's viscosity. The result of leveling is a reduction in the surface tension of the film. Figure 2.7 illustrates the leveling of a sinusoidal surface of a newly formed continuous molten film. For a film with a concentric sinusoidal surface, as shown in Figure 2.7, Rhodes and Orchard32 give the relationship between the leveling speed t and the viscosity and surface tension:

where a and a are the final and initial amplitudes, respectively, y is the wavelength, and h is the average thickness of the film. It can be seen from formula 2.11 that thicker film, smaller wavelength, higher surface tension and lower melt viscosity are beneficial to leveling.

However, the relative viscosity problem used in Equation 2.11 has not been fully resolved. Lin recommends using one of several available methods to calculate the stress due to surface tension.

Figure 2.7 Desirable sinusoidal surface

Then, from a predetermined flow curve, the viscosity at this shear stress is obtained; this may require measuring the viscosity at very low strain rates. On the other hand, Wu proposed31 to use the zero shear value of viscosity in Equation 2.11. Both methods will yield similar results unless the material is highly sensitive to strain rate (n < 1).

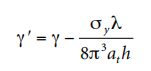

When a material has a yield stress, the surface tension needs to overcome the yield stress to begin to flow or level. Therefore, we replace λ in Equation 2.11 with λ:

This equation shows that coating fluids with low yield stress should stabilize rapidly. This flat requirement conflicts with the requirement for low sag or slump (high yield stress). Wu35 claims that a shear-thinning fluid with an index of 0.6 exhibits the lowest sag provided that the viscosity is 50 in the reciprocal 1 second. • Since such a fluid has no yield stress, it should stabilize well. This rheological behavior can be achieved in oligomeric powder coatings near the melting point, or in solution coatings with a high solids content. It is difficult to see how this behavior is achieved in all cases, especially for latex dispersions with yield stress.

- 1Application of Rheometer in Viscosity Test of Tomato Paste

- 2Understanding Rheometers in One Article - Principle, Application, Selection & Maintenance

- 3Rheometer polymer rheological performance

- 4Influencing factors of asphalt rheological performance

- 5How to calibrate the Rheometer? With calibrating steps

- 6Difference between Rheo-meter and Rotational Viscometer

- 7How to test rheological properties of colloidal materials

- 8What is the interaction between flow and viscosity?

- 9Paint rheology phenomenon: What is the effect of viscosity change after coating?