What is the interaction between flow and viscosity?

The driving force for the leveling process is surface tension. The forces resisting leveling are viscosity and, to a lesser extent, the elasticity of the coating. Therefore, for easy leveling, a low viscosity coating is recommended. However, low viscosity coatings cannot always be used. If the viscosity is low, it will be difficult to deposit heavier coatings. If the coating is applied to vertical surfaces, high viscosity is required to prevent sagging.

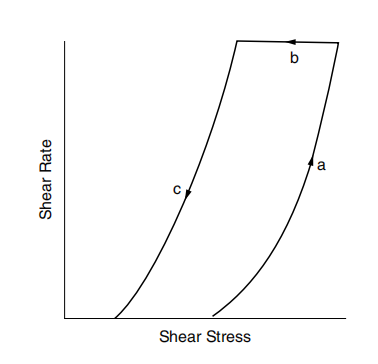

Figure 3.2 Thixotropic circuit

Waterborne paints are often pseudoplastic: they exhibit a rate-dependent viscosity. They may have low viscosity (20 to 30 mPa sec) at high shear rates (104 sec–1), such as experienced in roll coating operations, and higher viscosities at low shear rates (1 to 30 mPa sec). 3pa sec) (0.01 to 10sec–1), prevalent during the leveling process. Such coatings do not level well due to high viscosity at low shear rates.

Rheological index is sometimes used as an indicator of the leveling ability of a coating. Rheological index is defined as the ratio of high shear rate viscosity to low shear rate viscosity. If the rheological index is 1, the coating is Newtonian; if it is greater than 1, the coating is dilatant; if it is less than 1, the coating is pseudoplastic. A large rheological index favors good leveling; it should exceed 0.25 for an aqueous system with acceptable leveling properties.

- 1Viscosity of polypropylene (PP) amide measured by NDJ Viscometer

- 2Which Viscometer to Choose for Licorice Extract Viscosity Testing? How to Test?

- 3Application of Rotational Viscometer in juice viscosity test

- 4Working Principle, Classification and Application of Capillary Viscometer

- 5Principle, Characteristics and Application of Dial Viscometer

- 6Basic Principle and Application of Ceramic Viscometer

- 7Principle, Characteristics and Application of QND Viscometer

- 8Determination of epoxy resin viscosity by Rotational Viscometer

- 9Rotational viscometer selection suggestions