What is the principle of scratch testing?

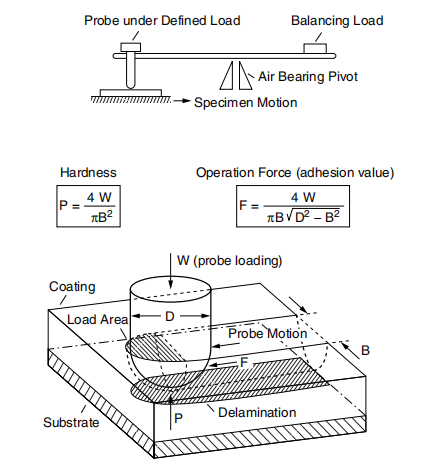

The figure below illustrates the principle of a test method in which the scratch resistance and adhesion of coatings can be measured. The loaded stylus draws on the film surface. It is clear that in a balanced system carrying a stylus there is a simple relationship between the applied load, whose strength can be easily controlled, and the shear force that ultimately causes the coating to fall off. A critical quantity is the radius of the tool tip, which needs to be measured with the same precision as the width of the contact area created during scraping.

Diagram of the scratch technique used to determine the adhesion of polymer films subjected to localized surface forces

It is recommended that the information obtained directly from the test be supplemented with additional data, such as the results of surface profilometers or scanning electron microscopy, which can provide insight into the details of the scratch topography. With such a specification, it is even possible to estimate adhesion values in multilayer systems. It can be seen what type of membrane failure occurs when these systems are subjected to scratch loads.

- 1Test principle and operation method of Pushen ZHY automatic scratch instrument

- 2How to test the scratch resistance of coats

Tom Mastrangelo

- 3Modern environment HY-IV type, scratch Tester operating instructions

- 4Modern environment ZHY type, automatic Scratch meter operating instructions

- 5How to use the Scratch Tester for Scratch Testing

- 6Discuss and analyze the failure mode of micron-scale dural soft foundation system in scratch test

杨杰; 沈耀; 蔡珣 - 《微米级硬膜软基系统在划痕试验中的破坏方式》

- 7How to comprehensively evaluate the bonding force of membrane base by scratch method?

- 8Scratch meter energy consumption measurement improvement scheme

黄林国 - 《单摆划痕仪能耗测量方法的改进》

- 9Impact scratch method for determination of bonding strength of Ni-P chemical platings