What is an ultrasonic pulse echo system?

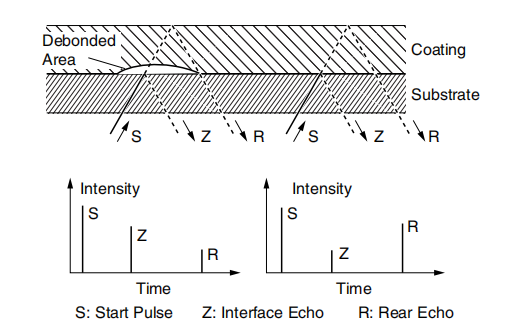

Ultrasonic echo monitoring, based on time-domain principles, is widely used to identify any irregularities in materials that are considered to be flawless. This method can also be used to assess the quality of the bond between a polymer coating and a substrate, regardless of its nature.

According to the figure, the incident ultrasonic waves will be partially reflected and transmitted at each interface of the test piece, including the backing. It is at the interface that the partially transmitted pulse then undergoes more or less total reflection on this free surface. Binding mass is expressed as the relative height of the pulse.

Ultrasonic pulse-echo technique for determining the location and size of adherent defects

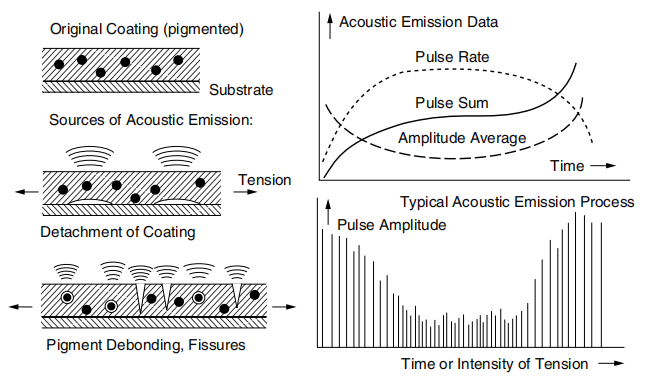

Application of Acoustic Emission Analysis in Coating Shedding Monitoring

When the bond at the interface is intact, the amplitude of the pulse reflected there will be quite low compared to the amplitude of the transmitted pulse that passes through the substrate and reflects onto its free boundary, subsequently appearing at the sensor. If it is assumed that there is a defect at the interface, containing air, or otherwise indicating that the joint has dissolved, the associated ultrasonic pulse amplitude will be greatly increased due to the very low acoustic impedance at this location.

As a result, the intensity of the transmitted pulse is reduced and its amplitude is greatly reduced. The area treated by ultrasound can be limited to a relatively small size. Thus, it is possible to virtually scan the test piece, row by row, to determine any places where adhesion strength may have been lost. The extent, and even the specific shape, of the defect area can be determined in the test program.

- 1Principle, Function, Application and Selection of Multifunctional Ultrasonic Thickness Gauge

- 2Principle, Application and Type Selection of Ultrasonic Thickness Gauge

- 3Principle, Application and Type Selection of Ultrasonic Thickness Gauge

- 4Principle, Application and Selection of Ceramic Ultrasonic Thickness Gauge

- 5The Principle, Application and Precautions of Copper Plate Ultrasonic Thickness Gauge

- 6Application of Ultrasonic Flaw Detector

- 7Principle and Application of Ultrasonic Thickness Gauge

- 8Ultrasonic Flaw Detectors: the right-hand man for nondestructive detection

- 9The role and application of ultrasonic flaw Detector