Explanation of the principle and structure of the wire rod applicator

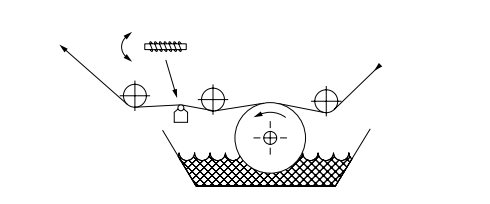

Wire wound metering rods (mayer-rods) have been used for over 75 years for liquid homogeneous flexible materials. They are the first tools to control coating thickness across the full width of a moving stencil. The use of sucker rods became popular in the 1980s due to quality improvements and industry trends. Wire wound rods have a wide range of applications, but find great appeal in the manufacture of tapes, labels, office products and flexible packaging. The original music sticks were made of ordinary carbon steel wrapped with music wire. Today's metering rods use precision ground stainless steel mandrels tightly wound with polished stainless steel wire at high speeds, on custom designed winding machines. The resulting product is a laboratory-quality precision tool that can precisely control coating thickness to within 0.0001 inch. (0.1 ml). A typical rod winding station is shown in Figure 19.1.

Figure 19.1 Typical coating system

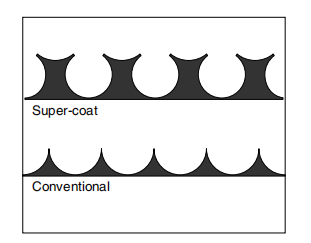

Figure 19.2 Groove shape of wire Bar Coater

It finds use in a variety of production applications from optical film manufacturing to wallboard panels. Wire-wound metering rods seem simple enough. A stainless steel rod is wound with a tight helix of wire also made of stainless steel. The wires can be so small that they are barely visible to the naked eye, or so large that the windings look like the coils of a heavy spring. Today, the industry has standardized on stainless steel rods because they can be used with nearly all coating fluids. Early rust and corrosion problems have been largely eliminated. Where abrasive wear is an issue, some converters use chrome plating to extend rod life due to the hard surface chrome has. However, chromium also has its disadvantages, as it builds up unevenly at the end of the wire, changing the shape of the wire and the resulting coating thickness. In addition, if not applied properly, the chrome can pit or flake off, contaminating the bath or causing an uneven coating. Several new products introduced since 1985 have further expanded the bar market. If you have streaking or stick cleaning issues, you can use a stick with a Teflon finish. Particles that may become wedged between the stainless steel wires tend to slide through, preventing buildup and subsequent streaking in the coating. Other users find that the Teflon surface is easier to clean, with some claiming that the rod lasts eight times longer than stainless steel rods. Super-Coat* rods are traditional rods with a second, smaller wire wrapped around the main wire of the regular rod. The dramatic change in the shape of the grooves between the wires has allowed some coating machines to produce controlled coatings more than twice as thick as conventional rods (see Figure 19.2). Other users have found that for any given coating thickness, the deeper grooves between the wires are spaced closer together and provide a smoother finish to the product.

Today's coaters have wider spools and higher operating speeds, producing many times the throughput of earlier equipment. At the same time, the market for coating materials requires more and more specialized products and, therefore, more frequent changeovers and setups. Replacing a coating rod requires very little downtime for changeovers compared to other coating methods, making precise control of coat weight without changing recipes a practical consideration for many coaters.

- 1Application of Mayer Rods in protective coating prepative

- 2Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 3Application of Mayer Rods in composite coating prepative

- 4Several Common Experimental Spreader Methods and Their Applications

- 5Application of Mayer Rods in Water-based ink Moulding

- 6Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 7The experimental case of OSP Mayer Rods at inks Moulding [with video]

- 8Why Do Film Applicators Need to Change Their Wires Regularly?

- 9Mayer-Rod (Mayer Rods) Preparative 2D Copper Nanosheets