Structural principle of metering bar coating system (painting station)

During the production coating process, the roll passes through a wetting station and then into a measuring rod, where the measured coating thickness is allowed to pass between the wires and excess liquid is returned to the reservoir. Coating fluids can be applied to the wetting station by several different methods.

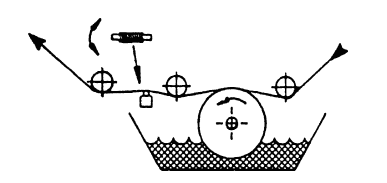

Figure 19.4 Immersion method

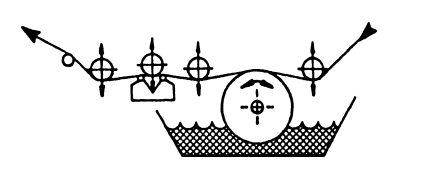

Figure 19.5 Applicator roller method

The net can be dipped directly into the tank (Fig. 19.4); or the applicator can rotate in the reservoir to transfer the liquid onto the web at its rotating top (Fig. 19.5). It is important to apply excess paint fluid at this station to allow the metering rod to do its job.

When using an applicator roll in a rod coating system, the speed of the applicator is not a critical factor. Additionally, the machine operator can adjust the applicator roll speed within a lateral range even while the machine is running. The web passes through a metering bar, which may be stationary or slowly rotating. The rotation can be in the same direction as the web or in the opposite direction. The choice of fixed rod depends on the movement of different coating machines and different products. A well-established spin speed will also vary from job to job, and processors will experiment to find a better program for each run. However, a common procedure is to slowly rotate the rod in the opposite direction to the web motion. Spin flushes the coating material between the wires, keeps the wire surface wet and prevents some liquids from setting and hardening. The rotation also distributes any abrasive wear evenly on the wire and prevents flat spots from forming. The purpose of the metering rod is to remove excess coating liquid so that a measured amount passes between the wire windings. The net should pass over the rod to allow excess liquid to fall back into the tank. However, the web does not have to be perfectly level, as long as excess coating can be returned to the tank by gravity. Metering rods for the production of coatings are available in various sizes. Common mandrel diameters are very small (3/16 and 1/4 inch), but sizes up to 1 inch diameter are also used. The main advantages of small diameter rods are low cost and ease of storage and handling.

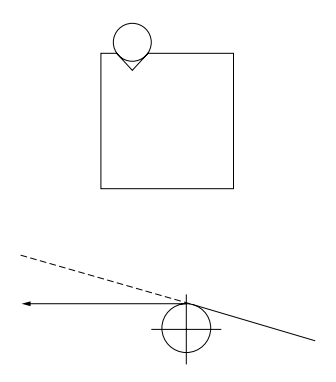

These thin rods need to be supported in the coater as they are not rigid and will deflect with pressure from the web. There are several types of rod holders commonly used; the simple one is a square rectangular bar machined into it with a "V" shaped groove. The rod holder fits between the side frames of the applicator and the metering rod rests in the groove. The "V" grooves should be ground and polished to minimize wear on the bar and should be fitted exactly, at right angles to the direction of web travel and parallel to the idler rolls of the machine (Figure 19.6).

The rod coating station should be designed to ensure tight contact between the reel and the metering rod wire. Winding angle, which is the angle between the direction of the reel when the reel is close to the reel and the direction of the reel when it leaves the reel, should be 15° for heavy reel tension and 25° for light reel tension ( Figure 19.7).

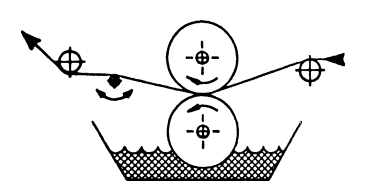

Web tension is a critical factor in the design of a rod coating station. When the winding angle is 15 ~ 25°, the reel needs to be tight enough to ensure close contact with the measuring rod, but not so tight that the reel is pulled and deformed by the wire. Adhesive and some other liquid freezes between the coils of the rod every time the applicator stops. Many coaters have a "snap off" feature, which is a mechanical means that automatically separates the web from the rod whenever the machine is turned off. This allows quick removal of the rod for rinsing and cleaning before the coating material has a chance to condense between the wires (Fig. 19.8).

This automatic release feature also simplifies changing sucker rods during production. One method used by coater manufacturers is the rocker trip system. While the coater is running, a series of idler rollers press the web against the metering bars. When the machine stops, the idler roller rises automatically to lift the reel away from the metering rod. At the same time, a water flushing system can be activated to remove coating material from the fuel rods prior to installation. Other techniques include lowering the measuring rod and its support when closing the applicator.

Figure 19.8 Automatic Throwing

Figure 19.9 Smooth bar

pole station change

Every coating application is different. Converter has created many unique rod coating systems, which they developed through experiments in the laboratory or actual production. A smooth rod is a finely polished measuring stick without wires that serves several different purposes. It can be used in the web path after gravure cylinder printing to eliminate etched patterns and enhance the coating surface. It can also be used when the viscosity of the coating liquid prevents it from leveling due to surface tension after winding the metering rod (Fig. 19.9).

When it is necessary to meter large quantities of coating fluid off the drum, two wire wound rods should be used in series, spaced 1 or 2 inches apart. separate. The first rod has the larger wire size to correct most of the excess liquid, while the second, smaller wire controls the finished coating thickness.

A typical painting station might use one or two measuring rods, there is also a position for a gloss rod which can be used for some applications. Coating rollers apply the liquid to a moving roller, which is metered by one or two rods, and then it can be flattened by smooth rods. A complete coating station design also needs to take into account drainage, filtration and suction of the coating solution, control of the wet edge of the roll, and separation of the metering rod when the machine is stopped.

- 1Application of Mayer Rods in protective coating prepative

- 2Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 3Application of Mayer Rods in composite coating prepative

- 4Several Common Experimental Spreader Methods and Their Applications

- 5Application of Mayer Rods in Water-based ink Moulding

- 6Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 7The experimental case of OSP Mayer Rods at inks Moulding [with video]

- 8Why Do Film Applicators Need to Change Their Wires Regularly?

- 9Mayer-Rod (Mayer Rods) Preparative 2D Copper Nanosheets