How to design lip for slit coating?

Lip adjustment design

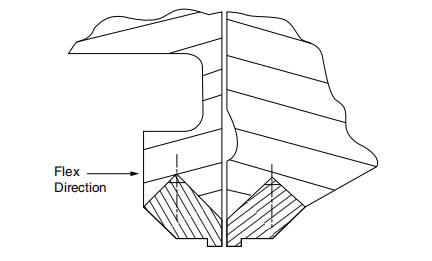

The two methods of adjusting the lip opening are the elastic lip (see Figure 20.4) and the sliding lip (see Figure 20.5). Both designs have proven effective in wipe coatings. The flexible lip-die design is based on the hinge effect (see Figure 20.4), allowing smooth, accurate adjustment on a relatively narrow centerline. This one-piece concept also eliminates parting lines and spoiler steps on the interior surfaces.

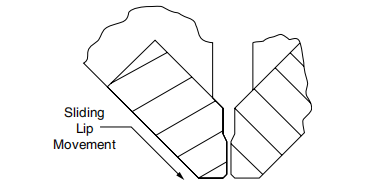

Slide the lip die (see Figure 20.5) to bolt the lip to the die body and use the push-pull adjustment bolt to adjust the lip position. This system has obvious disadvantages. The clamping force needs to be strong enough to seal the body and lip. However, this force needs to be overcome when moving the lip position during production, and the movement between the lip and the body results in a series of unpredictable jumps. Another disadvantage is the cross-sectional size of the lips and the physical spacing of the webs. The third disadvantage of the sliding lip is the deformation of the parallelism of the lip surface after adjustment.

Figure 20.4 Flexible lip adjustment.

Figure 20.5 Sliding lip design.

lip wipe design

Most low viscosity paints require some wiping shear to smooth the fluid onto the coil. This wiping action is a balancing act that creates enough shear to force the coating to lay without the lip acting like a dam.

Coating different fluids on different substrates at different coat weights and speeds requires changing the wiper face design. These designs are a departure from techniques previously used for slot die coating (roll smoothing rods and knives).

In general, four basic lip shapes are used today:

High shear flat wiper lip:

Medium cut flat lip:

Scraping lip of middle shear pole:

A sharp blade wipes lips:

- 1Application of Slot die coaters in Lithium Battery Coating

- 2Installation of the material head of the slit coater [including video demonstration]

- 3Operation demonstration of slit coating machine [including video explanation]

- 4How to clean the coating mold?

- 5How to realize the automatic control of slit coating

- 6Points to pay attention to in the design of support rollers for slit coating

- 7Principle and method of mold positioning for slit coating

- 8Principle and design of shunt pipe for coating hanger mold