What problems does the extrusion porous roll system mainly solve?

A recently developed extrusion roll coating system consists of a slot nozzle coating head positioned adjacent to a slow speed "nozzle roll" (see Figure 22.3). Fluid is coated on a "nozzle roll" and transferred to an adjacent "applicator roll" which in turn contacts the coated web for fluid transfer. The relative speed ratio between "nozzle roller" and "applicator roller" is about 1:30.

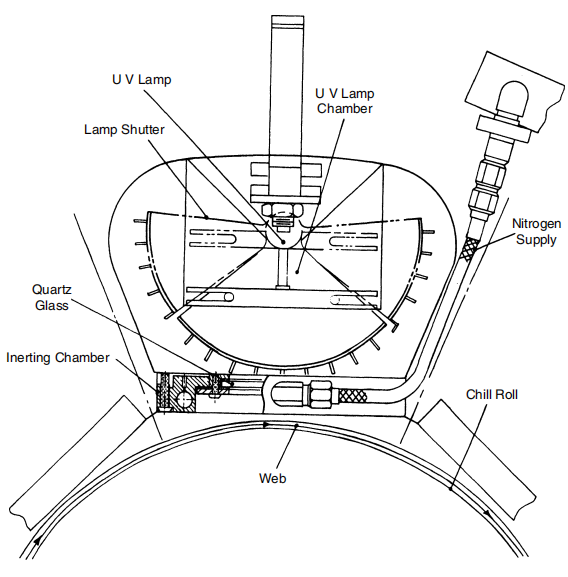

Test reports indicate that curable coatings have poor shear properties and that the speed ratio between the rolls depends to some extent on this limitation. Shear properties can be improved by heating the rolls, but this is not always effective, and the result is small spots of 1 to 2 mm or larger in the coated web, or transverse bands of the coating (flutter), whereas Not instead of a smooth, even coating. Likewise, a conventional roll coater comprising multiple rolls has a similar effect (see Figure 22.4). This phenomenon is associated with fluids with poor flow and expansion properties. The viscosity of an expanding fluid increases with increasing shear rate, as shown in Figure 22.5. In either case, the actual applied coat weight is influenced by the web substrate, surface condition, silicone product properties and application method.

Most coating processes are capable of applying these coatings within the industry standard range of 1.3 to 1.6 g/m2; however, the type of coil greatly affects the final coating weight. Our research revisits current methods of applying curable silicones, allowing us to develop an alternative method to overcome the shearing problem. This design became Acumeter's extrusion porous roll coater system. The system consists of a perforated stainless steel metal roll, an adjacent gumming roll and a laminating roll. A schematic diagram of such a coating machine is shown in Figure 22.6. The perforated rolls receive a fluid supply from a volumetric metering system that is synchronized but proportional to machine speed. A detailed schematic of a porous roll is shown in Figure 22.7.