Composition, structure and principle of rotary wire mesh coating machine

Shortly after the introduction of the multi-colour printing presses, monochrome printing units were also introduced, which over the years have found their way into a wide range of applications, such as wallcovering printing, hard floor production, technical paints, artificial leather production, and last but not least: as a single color printing presses.

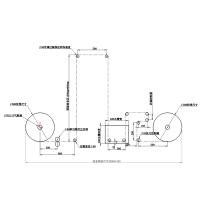

Screen coating equipment (Fig. 23.1) consists of the following parts:

• Screens are seamless, perforated nickel sleeves. The degree of perforation is indicated by the so-called mesh number, which indicates the number of holes per linear inch.

• Scrapers, installed in the screen, serve as supply and distribution pipes for the slurry. Scraper blades mounted on this pipe push the paste out of the screen walls.

• Whisper blade smoothes applied coatings.

The amount of paint used is determined by four factors:

• Choice of mesh

• Squeegee pressure: the angle formed between the scraper and the screen (the smaller the angle, the higher the added value.)

• Viscosity of slurry

• Regarding the drawdown blade setting of the counter pressure roller

Figure 23.1 Screen coater. 1: Network; 2: Scraper; 3: Screen; 4: Whisper Blade; 5: Scraper.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative