What are the components of the flexo printing system?

In fact, the swatch is an important part of the flexo printing machine. Today, only two printing platform systems are still of general and popular interest – the three-roll system or ink fountain roll color deck, and the two-roll system or ink fountain-less color deck. The latter has grown in importance in recent years and has grown in popularity as it allows for higher print quality.

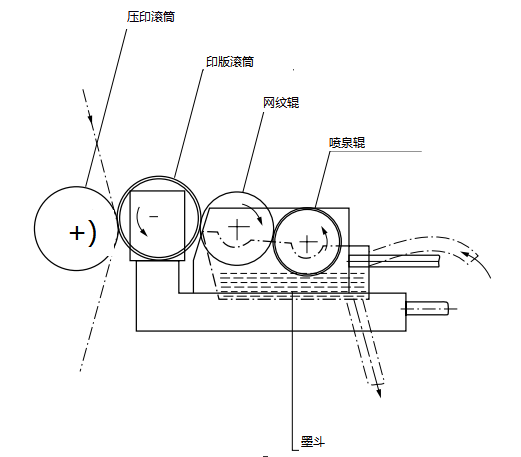

Figure 25.5 Fountain roller color table three-roller system

Three Roller System (Fountain Roller Color Deck)

The three-roll printing platform was developed decades ago and has been continuously improved. It is the version of deck commonly used in flexo presses today. It is relatively simple to operate and set up, offers a great deal of flexibility, and until a few years ago was a suitable design for all user requirements. A traditional three-roller printing platform is mounted on a pair of frames or consoles, usually consisting of a pair of angular bearing housings that carry the plate cylinder and a pair that accommodates the inking rollers (i.e., the anilox and fountain cylinders). Additionally, a device to receive the ink fountain will usually be included. In order to change the plate cylinder to print different repeat lengths (or to adjust the impression), the plate cylinder with its angular bearing brackets is loaded or unloaded horizontally to or from the impression cylinder. This is done mechanically, hydraulically or electrically. The same applies to the ink fountain and anilox roller as well as the ink channels (Fig. 25.5). This is accomplished by manual or electric adjustment of the threaded shaft or, more recently, by computerized systems providing varying levels of automation.

When the machine is stopped (that is, when printing is interrupted), the plate cylinder needs to be lifted off the impression cylinder and web to prevent the plate and substrate from sticking together. Thus, the plate cylinder is slightly raised or retracted horizontally and vertically. At the same time, the plate cylinder needs to be stopped and disengaged from the anilox roll so that no more ink is transferred to the plate. To prevent the ink on the ink rollers from drying out when the printing press is stationary, the anilox and ink fountain rollers need to continue to rotate, driven by separate motors. To prevent plate wear and damage, the peripheral speed of the anilox roll needs to always be equal to the surface speed of the plate on the printing cylinder.

With a three-roller printing platform, the amount of ink transferred to the substrate can be varied by changing the gap between the ink fountain and the anilox roller. This is the advantage of the three-roll system. However, an inherent disadvantage is that variations in speed necessarily result in variations in the quality of the ink transferred to the plate, which in turn causes color deviations in the printed image.

Two-roll or passive printing station

New techniques for flexo plate system design are relatively new and require significant engineering effort and extensive experimentation to arrive at acceptable solutions.

In a two-roll system, the plate cylinder and anilox roll with drawdown blade assembly replace the previously used ink fountain roll (Figure 25.6). Almost all scraper units are designed for lateral reciprocating scraper movement. Loading of the drawdown blade onto the anilox roll is mostly done pneumatically, with fine adjustment of the contact pressure.

Initially, anilox rolls only carried conventional or positive doctoring, but over the past two years, negative or reverse angle doctoring has become generally accepted and preferred. Press operators throughout the industry report more consistent and better results with contra-chambered squeegee blades, especially when doing fine finishing work on high-speed wide-format presses. This is due to the deck's ability to provide a finer, more uniform and precisely defined ink application across the entire width of the web and across the entire range of machine speeds. As an added benefit, wear and tear on the anilox roll and drawdown blade can be minimized if the drawdown blade is carefully mounted to the anilox roll with minimal contact pressure. In addition, ink consumption is greatly reduced, with no excess ink being transferred from the anilox roller surface to the printing plate. This dual-roller or fountainless printing platform with a contra-chamber drawdown blade system has been increasingly used throughout the industry and can be considered the printing platform system of the future. Most of the accessories and options for flexo printing presses are the same as those used for offset and gravure printing presses, and do not have any specific process-related characteristics.