What is pulsed jet printing and what are the advantages and disadvantages?

In contrast to continuous inkjet printers, drop-on-demand systems create ink droplets only as needed, eliminating the need to control excess droplets. These systems are inherently binary; either the droplet is ejected to be placed on the receiver sheet, or it is not.

Most of the system complexity in pulsed inkjet printers lies in the print head, since no recovery mechanism is required. Typically, pulse-jet printheads have a pressurized ink reservoir held directly behind the nozzle or orifice. When activated by an electrical pulse, ink droplets are ejected and directed onto the page.

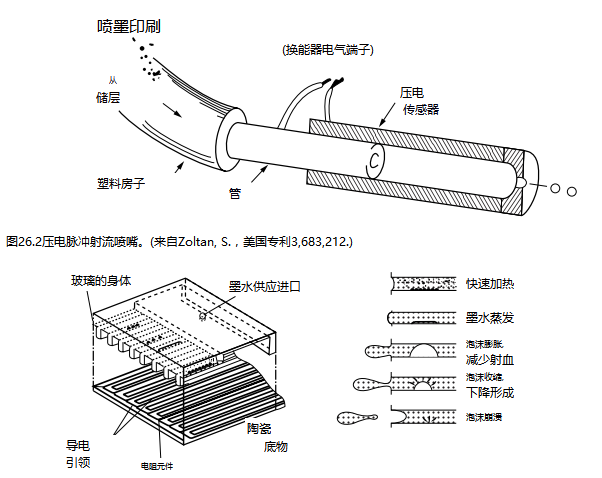

There are two basic methods of activating ink droplets. The earlier pulse-jet models used either squeezed the ink chamber at one end or pushed a piezoelectric transducer against the ink chamber. Figure 26.2 shows a schematic diagram of the piezoelectric method. Another method, heat-activated drop ink, is gaining popularity due to developments by HP and Canon. The heater creates bubbles of ink vapor that force the ink to drip out of the nozzle (Figure 26.3).

Most newer inkjet printers use pulse jet technology for general purpose printing applications. Advantages include mechanical simplicity, low hardware cost, and simplified logic. However, there are also disadvantages: drop-on-demand inkjet printers are more sensitive to shock and vibration, and have slower dot speeds (sometimes as low as 3 kHz). Additionally, market acceptance has been slow, partly due to early reliability issues caused by dry ink or paper dust clogging nozzles.

Figure 26.3 Thermally activated Canon PulseJet printhead. (From Jaffe, AB and Mills, RN, "Color Hardcopy for Computer Systems," SID Proceedings, Vol. 24/3, 1983, pp. 219-234.)

- 1What is inkjet printing?

- 2What are the printing substrates and printing inks?

- 3How are printing plates made?

- 4What is screen printing?

- 5Measuring the smoothness of paper during printing by water trace method

- 6RYDJ Printing Proofing Machine (Flexo Printing) Instruction Manual

- 7Talking about the standardized management of gravure proofing

殷幼芳 - 《凹版打样规范化管理》