What are the potential applications of diamond and diamond-like carbon films?

The development of PACVD and DIOND ion beam enhanced deposition techniques enables the deposition of a range of diamond and diamond-like carbon films with various operating characteristics. The application of each technology will depend on the desired film properties and the temperatures the component to be treated can withstand during the coating process.

The high-temperature PACVD process is mainly used in the field of semiconductor devices, because semiconductor and ceramic substrate materials can withstand high processing temperatures.

Applications in the field of semiconductor electronics include the production of active semiconductor components (amplifiers, oscillators and electro-optical components) operating at higher switching speeds and higher temperatures (and thus power levels), effective heat dissipation layers and insulating layers for protection against Oxidation and chemical contamination.

The availability of the DIOND ion beam enhanced deposition process, which produces a range of diamond and diamond-like carbon films at low temperatures and can be deposited on virtually any substrate, enables many applications of diamond coatings. Wear-resistant surfaces are now being produced for a variety of precision tools and wear components such as gears and bearings. The dielectric properties of the film make it useful as a protective coating for magnetic recording media on computer fixed disks, as well as for the magnetic recording heads themselves. Since films can be made optically clear, optical components such as lenses and mirrors can be surface treated to prevent corrosion and scratching. The film can also be used to reduce surface friction on components and to produce graphite self-lubricating layers for applications where conventional lubricants cannot be used.

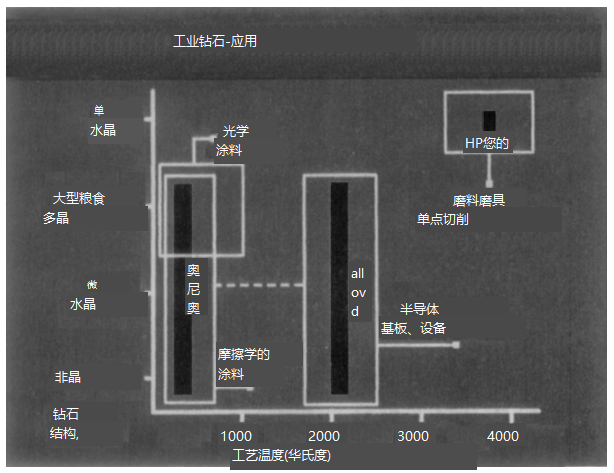

Figure 34.3 Potential application areas of diamond and diamond-like carbon films shows a continuum of film properties and processing temperatures. The PACVD process will be used primarily for semiconductor electronics applications, while the ion beam enhanced deposition (DIOND) process will be more widely used for the deposition of tribo-coatings for engineering machinery and optical components.

The availability of processes capable of depositing diamond and diamond-like carbon films on the surface of engineered components offers opportunities to improve the operational performance of many existing products as well as to develop a variety of new products in the semiconductor, electronics, optics, computer and mechanical components industries. Key to the successful use and application of these new industrial diamond and diamond-like films is an in-depth understanding of the range of film properties that can be produced, as well as the correct choice of techniques for depositing them.

- 1Application and Experimental Study of Film Coating Adhesive Technology

- 2Film coating thickness measurement

- 3What are the characteristics of diamond and diamond-like carbon films?

- 4What are diamond and diamond-like carbon films?

- 5Preparation of composite films by spin coating

王君涵 - 《大连理工大学》

- 6What is nylon film?

- 7How to paint on PVC surface?

- 8Analysis and Countermeasures of Adhesion of UV inks on Film stickers

晓晓 - 《UV 油墨在薄膜不干胶材料上黏着力不良故障分析》