Coating on rough substrates How to accurately measure coating thickness non-contact and non-destructive?

Tumoshi cleverly uses optics to obtain a large number of average values for automatic data compensation. Even if there are changes in roughness, unevenness, waviness and other factors on the surface of the substrate and coating, the measurement accuracy will not be affected.

Limitations of Traditional Dry Film Thickness Gauge

Traditional dry Film Thickness Gauges usually can only accurately measure the coating thickness on a flat or smooth substrate surface. Once there is roughness, waviness or unevenness on the substrate surface or coating surface, it will seriously affect the dry film thickness measurement. Meter repeatability and measurement accuracy.

In addition, factors such as substrate material, coating composition or surface curvature can also cause significant deviations in the measurement results of the dry Film Thickness Gauge.

Coating Thickness Measurement Solution for Rough Substrates

Tumoshi ATO non-contact thickness measurement technology cleverly uses optics to obtain a large number of average values for automatic data compensation. Even if there are changes in the roughness, waviness, and unevenness of the substrate or coating surface, the measurement accuracy will not be affected.

Tumoshi has broken the limitations of the traditional dry Film Thickness Gauge due to the roughness of the substrate, the deformation of the magnetic induction line caused by difficult-to-measure parts such as the edge or curved surface, and can quickly adapt and reliably and accurately measure the coating thickness.

Other outstanding advantages

1. Non-contact and non-destructive thickness measurement method;

2. Unlimited substrate and coating materials;

Not only can it accurately detect the coating thickness on metal substrates, it is also suitable for detecting non-metallic substrate materials such as carbon fiber, glass, rubber, wood, etc.; the coating type is suitable for powder coatings, paints, adhesives, Dacromet coatings, lubrication coating etc. No need to replace the measuring probe, one machine is universal, and the operation is simple;

3. The test operation is simple, and the test time only takes 0.5 seconds;

4. There is no need to strictly control the measurement conditions;

There is no need to strictly measure the shape of the workpiece, the color of the coating, and the angle and distance of the measurement. The applicator can also accurately measure the thickness of small areas, substrate edges, curved surfaces, etc.;

5. Very suitable for use in production line or laboratory environment;

Provide a variety of portable and online models to meet the uninterrupted thickness measurement, real-time data archiving and feedback, which is conducive to improving the quality of product spraying;

6. Adopt xenon lamp safety light source;

Painter uses xenon lamp safety light source, which does not pose any safety hazards to workpieces and operators;

7. Both dry film and wet film can accurately measure film thickness;

1. Accurate thickness measurement for rough substrates

Tumoshi is based on ATO non-contact non-destructive patented thickness measurement technology, even if there are changes in the roughness, unevenness, waviness and other factors on the surface of the substrate and coating, the measurement accuracy will not be affected.

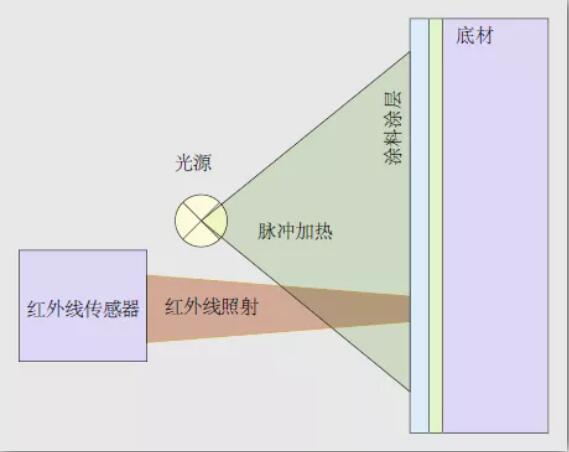

The device heats the coating to be tested in a pulsed manner, and the built-in high-speed infrared Detector records the temperature distribution of the coating surface from a distance and generates a temperature decay curve. Finally, the specially developed algorithm is used to analyze the surface dynamic temperature curve to calculate and measure the coating thickness to be measured.

Since the heat always penetrates the coating vertically, the operator can accurately measure the thickness without strictly controlling the test angle and distance when using the applicator, which greatly improves the convenience of operation.

Case Studies

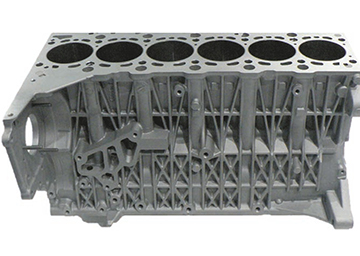

[Application] The original production process of cylinder engine crankcase is traditional gray cast iron inserts, and the new process is hot-melt spraying iron-based coating; the new process requires fast and accurate coating thickness measurement for thermal spraying coatings; but in order to produce enough Excellent coating adhesion, the new process roughens the cylindrical surface of the crankcase. Hence the need for thermal spray coating thickness measurements on rough substrate surfaces.

[Difficulties encountered] For measuring the coating thickness on rough substrate surfaces, the traditional dry film measuring instrument not only has low accuracy and poor repeatability, it is not suitable for accurate monitoring of product quality; and the microscope test is very time-consuming and can only be randomly selected, and Destructive testing of artifacts is required. Therefore, the above two thickness measurement methods are not suitable for monitoring the coating thickness of this process;

[Better thickness measurement solution] Tumoshi's precise and non-destructive thickness measurement system. The ATO technique enables fast and reliable measurement of coating thickness on roughened substrate surfaces.

【Measurement process】

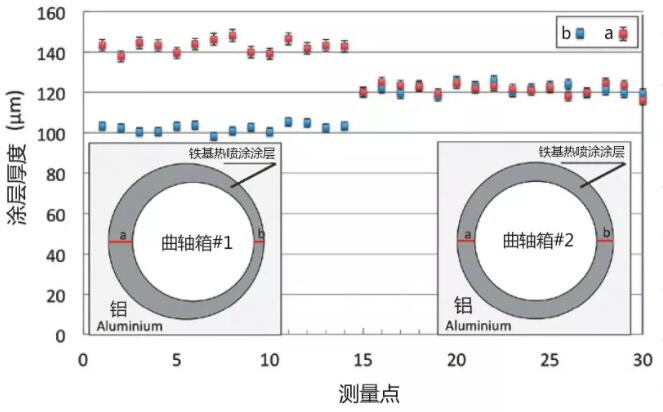

1. Products: Crankcase 1 and Crankcase 2;

2. Test equipment: Tumoshi non-destructive thickness measurement system;

3. Test area: Non-contact measurement of the thickness of the iron-based thermal spray coating from the bottom to the top of the cylinder, the measurement areas are a and b;

4. The measurement picture is as shown in Figure 1:

Figure 1: Actual measurement picture

From the measurement results in Figure 2 below, it can be seen that the magician can:

1. Easily and non-destructively measure the coating thickness at designated positions (a and b) in the cylinder; intelligently and accurately identify the coating thickness of different test areas for different products;

2. In addition to effectively assisting the manufacturer to monitor the thickness of the thermal spray coating, it can also assist the manufacturer to determine the concentricity of the fine boring hole, so as to perform accurate correction and quickly adjust the asymmetry.

Figure 2: Measuring points 1-15 for crankcase #1 and measuring points 16-30 for crankcase #2

【Experimental results show that】

Even when testing the coating thickness on high-roughness substrates, Tumagist can achieve a high measurement accuracy advantage of 1%~2%.

In continuous production, Tumagist can effectively assist manufacturers to continuously monitor the true film thickness of workpieces and reduce rework rates.

- 1Nondestructive measurement of dry coating thickness

- 2Coated steel coatings - Determination of dry-film thickness

- 3Application scheme of coating thickness test on wood board [with test video]

- 4Curved plastic coating thickness test application scheme [with test video]

- 5PosiTector200C ultrasonic coating Thickness Gauge on concrete coating thickness measurement application

- 6Coating Metering rodsFAQ

- 7Measuring method of nondestructive heat spray-on lining thickness

- 8Coulomb Thickness Gauge FAQ and Its Solutions

- 9What are the FAQs for paints Thickness Gauges? How to solve it?