How to measure gloss? (principle analysis)

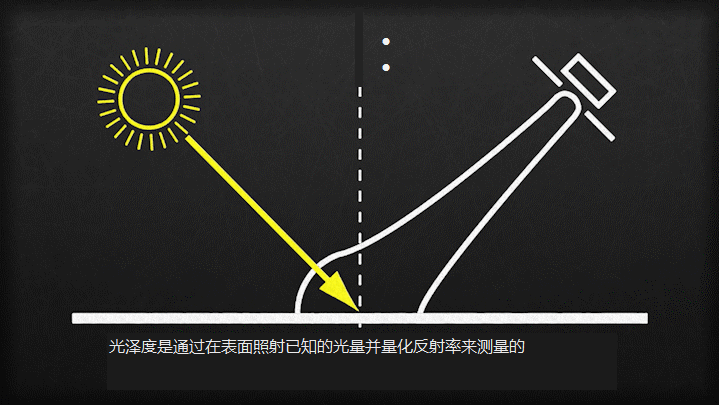

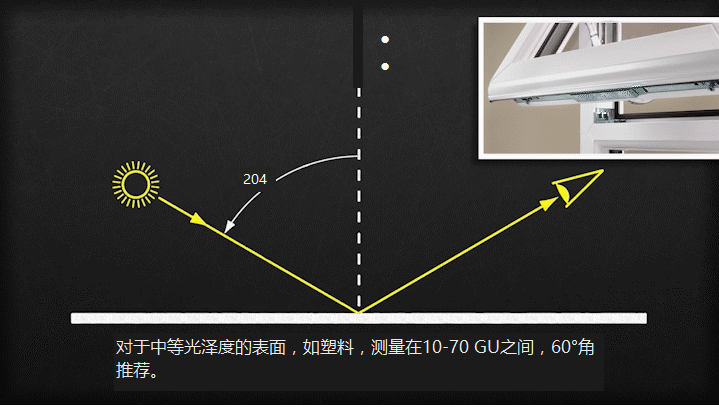

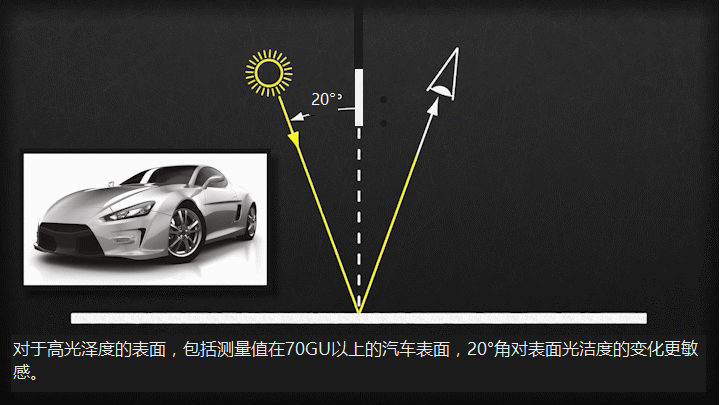

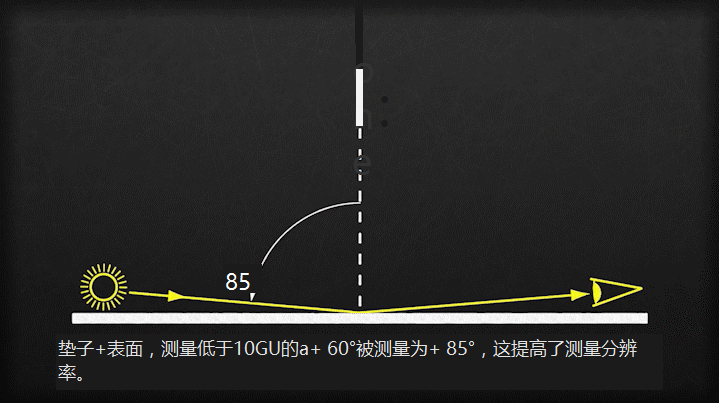

A gloss meter (also known as a gloss meter) is an instrument used to measure the specular reflection (glossiness) of a surface. Gloss is determined by projecting a beam of light onto a surface at a fixed intensity and angle and measuring the amount of reflected light at an equal but opposite angle. There are many different geometries that can be used for gloss measurement, each depending on the type of surface being measured. For non-metals, such as coatings and plastics, the amount of reflected light increases with the angle of illumination because some of the light penetrates the surface material and is absorbed into it, or is diffusely scattered from the surface material depending on its color. Metals are more reflective and therefore less angularly dependent. There are a number of international technical standards available which define the use and specifications of different types of gloss meters for various materials including paints, ceramics, paper, metals and plastics. Many industries use gloss meters in quality control to measure the gloss of products to ensure consistency in their manufacturing processes. The automotive industry is a major user of gloss meters, with applications extending from the factory floor to the repair shop.

How to Measure Gloss

Construction of Gloss Meter

A typical gloss meter consists of a stationary mechanical assembly that includes a standard light source that projects a parallel beam of light onto the test surface to be measured, and a filter Detector that receives the light reflected from the surface, Figure 1. The ASTM method states that the illumination should be defined such that the source-Detector combination is spectrally corrected to provide a CIE luminous efficacy V (l) with a CIE source SC. Many instruments are commercially available that meet the above criteria in terms of measurement geometry. These instruments are calibrated using reference standards typically made of highly polished flat black glass with a refractive index of 1.567 for the sodium D line and a gloss value of 100 for each geometry.

- 1Gloss inspection method of slurry inks

- 2Principle and Application of Glossiness Tester

- 3Working Principle and Application of Metal Gloss Meter

- 4Basic principle and application analysis of insulating paint gloss Detector

- 5Working principle and application analysis of film Glossmeter

- 6Principle and application analysis of microporous gloss meter

- 7 FZ/T 01097 Analysis of fabric gloss test method

- 8Evaluation and Application of Optical Properties of Powder coatings

- 9Coating coatings - Determination of surface gloss and Gloss meter