5 Ways to Improve Ball Mill Efficiency

As we all know, the ball mill is the key equipment for grinding materials after crushing, and it is an indispensable equipment in mineral processing plants, metallurgy, chemical industry, cement and other fields. However, how to improve the efficiency of the ball mill has always been an important topic of concern to engineers and users. In order for milling to be effective, we need to be familiar with these factors first. Mainly ball mill structure, rotating speed, ball milling medium, liner, feed and feed speed, etc.

Ball mill structure

The structure here refers to the ratio of the length of the ball mill to its diameter. According to industrial tests, the capacity varies with the type of ball mill; even for the same ball mill, the energy consumption and grinding efficiency are also different. One of the factors is a function of diameter and length. The length of the ball mill affects the fineness of the output. If the cylinder is too short, the required fineness cannot be achieved; if it is too long, the material will be on the ground, resulting in waste of energy consumption. Therefore, the length and diameter of the ball mill should be properly designed. In this way, the efficiency of the ball mill is improved through proper crushing and energy consumption. The theoretical ratio of length to diameter is between 1.09 and 1.5. At the same time, according to different requirements, we can customize ball mills with different length-to-diameter ratios for customers.

1. Cylinder speed

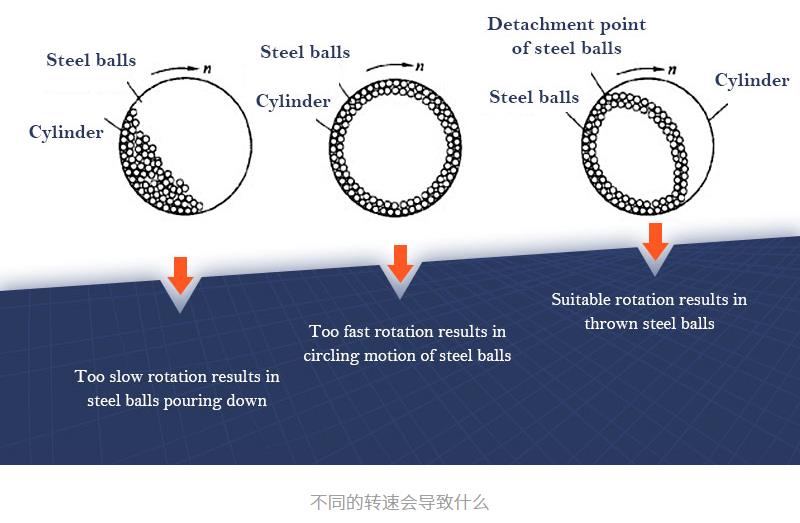

Proper barrel speed of the ball mill helps to make full use of the impact and grinding action of the grinding media. Greatly improved the efficiency of the ball mill. The cylinder cannot rotate at too high or too low a speed. The image below clearly shows the difference.

If the speed is too low, the grinding media will dump, causing the ball mill to grind "gentle". Strong impact and grinding forces cannot be produced. And if the speed is too high, the grinding material will move along the inner barrel together with the grinding media. Then the grinding media and materials become "close friends", and high grinding efficiency cannot be produced. Only when the cylinder rotates at the design speed, the grinding media will be thrown into the proper position. Through the slide block, the grinding media can effectively impact and grind the material.

2. Grinding media

As a part of the direct contact with the material, the grinding media is an important factor to improve the grinding efficiency of the ball mill. The improvement of ball mill efficiency is mainly from two aspects: the proportion of grinding media with different particle sizes and timely media supplementation.

Proportion of grinding media of different sizes

The proportion of grinding media of different particle sizes includes the size and amount of media. Generally, the grinding media of the ball mill is made of appropriate materials into balls, and the most commonly used material is steel.

For different grinding requirements, the proportion of steel balls with different diameters is different. Larger diameter steel balls are mainly used for crushing and smaller ones for grinding.

If the proportion of larger steel balls is larger, the impact force generated by the falling of the steel balls will cause greater damage to the liner and increase the consumption of steel balls. And if there are more smaller steel balls than larger steel balls, the material will get more cushioning effect. And the grinding efficiency is reduced. Therefore, the proper ratio of different sized grinding media is very important. According to the feed size, if there are more large materials in the barrel, the operator should load more large steel balls. The opposite is true if there are more small materials.

Replenish the media in time

During the grinding process, the wear of the medium is inevitable, so it is necessary to replenish the steel balls in time. The proportion of supplementary steel balls should also be controlled. If the grinding medium is not added accurately, it is easy to get stuck in the cylinder and damage the machine. In order to add steel balls accurately, experts give some suggestions:

Screening of specific ores and grouping by size;

Analyze the crushing resistance of the ore, and calculate the exact ball diameter required for each group of ore by using the semi-theoretical formula of the ball diameter;

The principle of crushing statistical mechanics is used to guide the feeding of grinding media on the particle composition characteristics of materials. This is to obtain a greater probability of fragmentation.

In addition to the proportion and frequency of the grinding media, other factors such as the material and shape of the grinding media can improve the efficiency of the ball mill. Please consult a professional engineer for details. The optimized grinding media can increase the efficiency of the ball mill by about 30%.

3. Lining board

The liner is another part that is in direct contact with the material.

If the liner made of ordinary materials is too thick, the effective volume of the ball mill cylinder will be reduced. In addition, the thick liner increases energy consumption due to its heavy weight and reduces the production efficiency of the ball mill. So how to choose a hard material to make a thin and durable liner is an important issue.

According to experience and experiments, this material can be high manganese steel. High manganese steel is very wear-resistant, and the surface hardness of the liner made of it can reach HV500. Such materials can increase the wear resistance of the liner, increase the effective volume of the cylinder, and improve the efficiency of the ball mill. In addition, the shape of the liner affects the efficiency of the ball mill. For example, Ford Machinery provided customers with corrugated liners, which greatly expanded the contact surface area between the grinding medium and the material, enhanced the grinding effect, and received good feedback.

4. Feeding

Controlling feed refers to feed size and feed rate. It is a good principle to control the feed particle size, "more crushing and less grinding". Feeding speed refers to feeding the material into the barrel of the ball mill at a moderate speed.

Feed size

Studies have shown that ball mill efficiency is also related to the feed particle size. The larger the feed particle size, the longer it takes to grind the material to the desired fineness, the greater the power consumption and the lower the efficiency. The crushing efficiency is higher than the grinding efficiency, and a crusher can be equipped before grinding. This kind of crusher can be a jaw crusher with a large crushing ratio and a wide range of applications, or a roller crusher that increases ore microcracks through laminated crushing. But not the thinner the better. Too small a material size reduces grinding efficiency. Generally, the feed particle size is controlled between 25 and 15 mm (the feed particle size is affected by the diameter of the ball mill).

Feed rate

When the feed is too slow, it is easy to idling. This not only causes excessive crushing, wasting energy, but also causes serious wear and tear on the liner and grinding media. If the feeding speed is too fast, it is easy to produce material accumulation, which will seriously affect the grinding effect and reduce the efficiency. Therefore, a moderate feeding speed can further ensure full contact between the grinding medium and the material, improve the efficiency of the ball mill, and reduce energy consumption.

5. Other details to improve the efficiency of the ball mill

The above are the five commonly used methods to improve the efficiency of ball mills . And two other things are often overlooked. They are choosing the right model and doing regular maintenance.

A good start will double your results. For different materials, engineers will provide different types of ball mills. Maintenance is the escort to improve the efficiency of the ball mill.

- 1Factors Affecting the Grinding Efficiency of Ball Mill

- 2Structure, principle and working process of ball mill

- 3Introduction and comparison of advantages and disadvantages of 4 kinds of dispersed equipment

- 4Comparison of three different dispersion Applicators

- 5What factors affect the dispersion efficiency of horizontal ball mills?

- 6Factors Affecting the Capacity and Quality of Ball Mill Grinders

- 7Common problems and solutions of ball mill

- 8How to choose the right Ball mill?

- 9Ball mill works