What is the significance of coating Thickness Gauge calibration? How to calibrate? When to calibrate?

What is Calibration?

The term "calibration" has different meanings depending on the industry or context in which it is used. There is a good chance that someone you know has misunderstood the terms calibration and calibration interval as they relate to the coating inspection industry. They will be surprised to learn that not only can they not calibrate the gage themselves, but there is often no set recalibration interval.

To understand the difficulty of defining calibration terms, one only has to look at the myriad of definitions provided by major organizations. Given the challenges of defining a term for many types of instruments in many industries, it's not surprising that the interpretations differ.

A simpler approach is to explain calibration terms as they relate to a specific industry sector, in this case, the protective coatings industry. Here ISO, ASTM, SSPC, etc. generally agree.

Calibration for the coating inspection industry

ASTM D7091 describes the measurement of dry film thickness using a magnetic eddy current meter and is typical of many standards. It defines calibration as:

"...advanced, controlled and documented process of obtaining measurements of traceable calibration standards over the entire working range of the gage and then making necessary gage adjustments (as required) to correct any out-of-tolerance conditions. Coating Gauge Thickness gages are performed by the equipment manufacturer, their authorized agent, or an accredited calibration laboratory using a documented process in a controlled environment.The result of the calibration is the restoration/recalibration of the gage to meet/exceed the manufacturer's stated accuracy. "

Within that definition, there are a few terms that deserve further discussion:

"Traceable Calibration Standards": Fundamentally, the purpose of calibration is to ensure that instrument readings are within tolerance of a standard of known value. Quantifying these known values (weight, distance, etc.) is the responsibility of an organization called the International Bureau of Weights and Measures (BIPM).

BIPM collaborates with national metrology institutes such as NIST (USA), NPL (UK) and PTB (Germany), which maintain Standard Reference Materials (SRMs) for standard measurements such as length, weight and time. These SRMs are highly accurate artifacts that can be used as calibration standards for precision measuring equipment.

Since it is not affordable, effective or even possible for everyone to calibrate against SRMs, SRMs are used to calibrate primary calibration standards; secondary standards are used to calibrate working standards; and working standards are used to calibrate process instruments. Through this "chain" of standards, the instrument can eventually be traced directly to the SRM artifact without measuring the artifact.

Since an instrument or standard is always less accurate than the standard against which it is calibrated, the uncertainty increases as you move down the chain of standards.

The industry generally accepts a Test Uncertainty Ratio (TUR) of 4:1, meaning that the tolerance of an instrument is four times the standard uncertainty against which it was measured. For example, a coating Thickness Gauge calibrated to a standard with an uncertainty of ± 0.05 mils will have a specified tolerance or accuracy of ± 0.2 mils when using a 4:1 TUR.

All participating institutions recognize the validity of each other's calibration and measurement certificates under mutual recognition agreements signed by major national metrology institutes.

"Accredited Calibration Laboratory": ASTM D7091 limits the parties who may perform calibrations to "the equipment manufacturer, its authorized agent, or an accredited calibration laboratory by ...". While the first two categories are self-evident, the concept of an "accredited calibration laboratory" is less clear. ISO/IEC 17025 specifies the requirements for accreditation, which laboratories can obtain through accreditation bodies that are signatories to the International Laboratory Accreditation Cooperation (ILAC) agreement.

However, a laboratory's ISO 17025 accreditation is only for specific calibration activities. The scope of a laboratory's accreditation lists the activities for which the laboratory is accredited to perform, and the measurement uncertainties to which the laboratory is able to calibrate. If using a third-party calibration laboratory, it cannot be overemphasized that it is not only accredited, but that its accreditation includes the instrument you are trying to calibrate. While a large number of ISO 17025 accredited laboratories exist, few are accredited to calibrate coating inspection equipment.

Calibration certificate

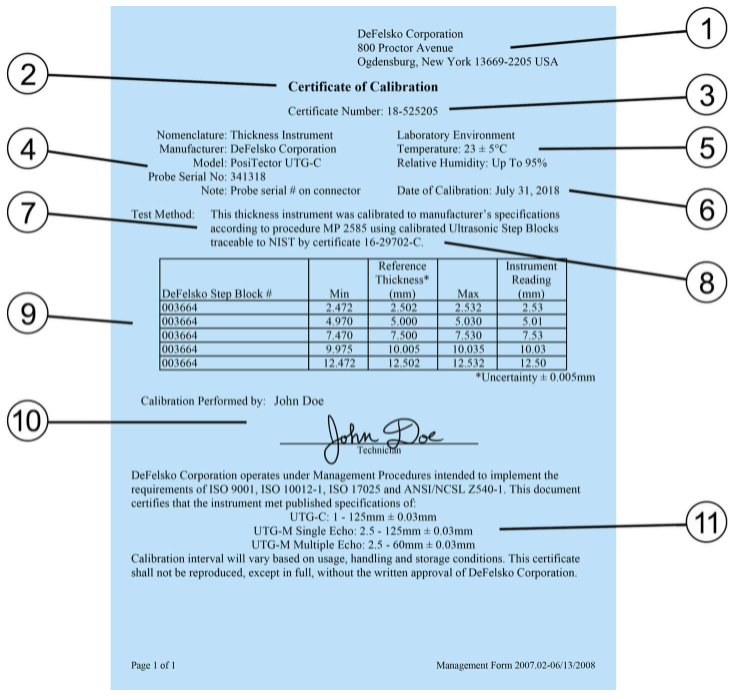

When an instrument is calibrated, a document called a calibration certificate is issued (Figure 1). This document documents the actual measurement results and all information relevant to a successful instrument calibration, including traceability to national standards. Work specifications usually require proof of recent calibration.

Many test equipment manufacturers do not provide calibration certificates. Instead, they may provide a "Certificate of Conformity," "Certificate of Compliance," "Certificate of Accuracy," or "Attestation." These are only the manufacturer's statements of accuracy, requiring the user to trust that the instrument will measure accurately. Such "certificates" do not meet the definition of calibration in ASTM D7091 and other standards, and are often insufficient to meet internal, contractual, or regulatory requirements.

While the form and content of calibration certificates vary, a proper certificate needs to contain certain minimum information to ensure compliance with ISO/IEC 17025 requirements. Figure 1 shows an example of a calibration certificate with each important attribute highlighted.

Figure 1 - Example of a calibration certificate

1) Identification of the calibration laboratory - The calibration certificate needs to indicate where the calibration was performed.

2) Title - Make sure the file is "Certificate of Calibration" or "Certificate of Calibration".

3) Individual Identifier - Each calibration certificate is one and should have an individual identifier such as a serial number or certificate number.

4) Identification of Calibrated Instruments - Calibration certificates should clearly identify the instrument, including serial number and any model information.

5) Environmental conditions in the laboratory environment - at least the temperature and relative humidity at which the calibration will be performed should be specified.

6) Calibration date

7) Identification of Calibration Method Used - Any calibration should be performed in accordance with established and approved procedures. Some equipment manufacturers publish their calibration procedures.

8) Evidence of Traceability - Traceability is the main purpose of a calibration certificate and evidence of traceability needs to be documented.

9) Calibration Results - Calibration certificates need to document the actual instrument readings against reference values and state whether the instrument readings are within tolerance of the reference standard.

10) Name, title and signature of the person performing the calibration

11) Statement of Accuracy - The certificate needs to state the uncertainty to which the instrument has been calibrated. This is usually the same as the manufacturer's specification, but may be limited by the capabilities of the calibration laboratory.

12) Accreditation body logo/information (unless the certificate is issued by the equipment manufacturer) - For certificates not issued by the equipment manufacturer, the logo or identification information of the body from the accredited laboratory shall be provided.

If a certificate issued by a calibration laboratory or instrument manufacturer does not contain these important attributes, it may not be a calibration certificate as defined by most standards and contracts.

when to recalibrate

Since the accuracy of most measurement equipment degrades with use, periodic recalibration (or recertification) is required throughout the life of the instrument. A calibration interval is a defined period of time between instrument recalibrations. As required by ISO 17025, most manufacturers do not include the calibration interval as part of the calibration certificate. Why? Because they don't know the frequency of use, environment and maintenance of measuring tools4.

One year is a good starting interval between calibrations if you are inexperienced with the instrument. This can be adjusted based on experience and periodic verification (see below). Customers with a new instrument can start their first calibration interval with the date the instrument was put into service (or date of purchase). The effect of shelf life is negligible, minimizing the importance of the actual calibration certificate date.

-

DONGRU DR120 Coating Thickness Gauge$ 168.00

-

-

DONGRU DR130 Coating Thickness Gauge$ 184.00

-

-

-

-

-

-

- 1Nondestructive measurement Coating thickness

- 2Principle, application and selection of traffic coatings Coating Thickness Gauge

- 3Principle, Application and Selection of Eddy current Coating Thickness Gauge

- 4Principle, Application and Type Selection of Electronic Coating Thickness Gauge

- 5Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- 6Principle, Application and Type Selection Analysis of Chrome Coating Thickness Gauge

- 7Principle, Application and Selection of Coating Thickness Gauge for inner wall of small pipe

- 8Basic principle and application scenario of steel Coating Thickness Gauge

- 9Principle and Application Analysis of Coating Thickness Gauge