What is the salt spray test and what are the international standards?

Salt spray test

Salt spray test, also known as salt spray test, is a common corrosion test method. Accelerated standardized test methods are one of the well-established and extensive procedures for testing and comparing corrosion resistance in a constant environment.

What is a salt spray test?

Salt spray test, also known as salt spray test, is a popular corrosion test method. Accelerated standardized test measures the corrosion resistance of steel and other materials exposed to salt spray or fog.

Invented in 1939, ASTM B117 was the first internationally recognized standard for salt spray or salt spray, followed by ISO9227, JIS Z 2371 and ASTM G85. Salt spray test is one of the most mature and widely used corrosion test methods in the world.

Application of salt spray test

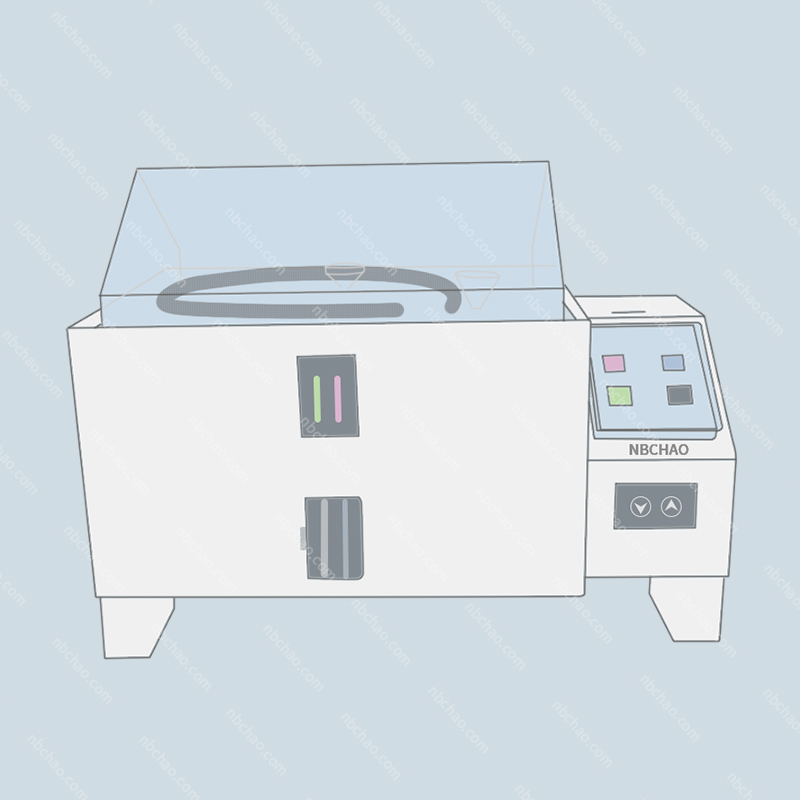

For corrosion testing, the material being inspected is placed in a salt spray Test Chamber. The workpiece is then exposed to an uninterrupted spray or mist of saline solution. Therefore, the name of the salt spray test comes from this. In addition to the Test Chamber, a prerequisite for a successful testing program is that the environment does not change and remains stable during the exposure period

In order to perform the test procedure according to ASTM B117, the temperature needs to be kept at 35 °C (+1.1 °C to 1.7 °C) Also, the pH of the test environment needs to be between 6.5 and 7.2, and a salt atmosphere is also important. It needs to consist of 5% Sodium Chloride and 95% ASTM D1193 Type IV water that is imported at a steady, predetermined air pressure. The duration of a corrosion resistance test depends largely on the material being examined and the coating of the metal. The Test Chamber needs to be constructed according to the standards applied.

Salt spray test standardization

Salt spray testing is a highly standardized corrosion testing procedure that complies with national and international standards. The performance of the Test Chamber, test procedures and test parameters, such as temperature, air pressure or pH value of the salt spray solution, are predetermined according to the above-mentioned standards. Test parameters need to be checked frequently in order to show compliance with standards and to ensure proper test conditions. As reference standards, ASTM B117 and ISO 9227 are widely accepted.

What is the difference between ASTM B117 and ISO 9227?

Established in 1939, ASTM B117 was the first internationally recognized standard for salt spray testing. This test procedure is widely accepted and has been considered the gold standard for corrosion testing for many years. ASTM B117 is an acyclic test. This means that the material being tested is constantly exposed to salt spray. This situation is a major failure in commonly used tests, since real-world weather conditions fluctuate.

The ISO 9227 standard is just as flawed as ASTM B117. The standard also exposes materials to long-term exposure to salt spray. Therefore, the test atmosphere is static, so the standard does not mimic real-world conditions. The main difference between the two corrosion testing methods is that ISO 9227 is globally accepted, while ASTM B117 is only an American standard.

Advantages of salt spray test

Salt spray testing has many advantages over other corrosion testing methods. One of the main benefits of the program is that testing is relatively inexpensive. Furthermore, the test duration is rather short compared to natural environments and provides quick results. Therefore, salt spray testing is used to quickly compare expected and actual corrosion resistance. Therefore, it plays an important role in quality control and is used to check the effectiveness of the production process.

However, salt spray testing has some disadvantages. It has nothing to do with the actual performance of the test material. For example, it can only provide results for the life expectancy of the coating in salt water. Also, this is a destructive test.

- 1Experimental principle and application analysis of experimental salt fog

- 2Working Principle and Application Analysis of Ceiling Salt Spray Tester

- 3Principle, significance and method of salt spray test

- 4Salt spray test NSS, ACSS, CASS difference

- 5Different test methods and similarities and differences of salt spray test

- 6Salt Spray Tester in salt spray testing

- 7Hardware salt spray test method

- 8Purpose and method of durability testing of building materials

- 9Cyclic corrosion test and its test procedures