What are the special requirements for spin-coated nanoparticles?

In many areas of organic electronics and nanotechnology, the casting and drying stages of the ink are an integral part of the technology and where all the "action" takes place. It is sometimes referred to as "the science of paint drying", and in all of the following examples some or all of the key processes occur during ink drying:

π-π stacking/crystallization of small molecules or polymers

Self-assembly of block copolymers

Phase Separation of Polymer-Fullerene Blends

Aggregation/assembly of nanoparticles and colloids

The importance of controlling this process cannot be overemphasized. In practice, the properties of a film depend not only on its physical properties (thickness, homogeneity), but also very much on processing (drying time and conditions). In contrast, in many of the more general spin-coating processes, such as applying photoresist, the results are largely independent of the exact application route. For this reason, variants of the usual technique are often used in organic electronics and nanotechnology - especially in research settings.

In particular, for industrial processes, spin coating is usually only recommended at speeds >1000rpm to ensure better uniformity.

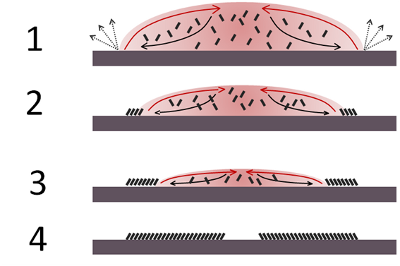

The image below shows how slow dripping without rotation can be a good way to deliver highly ordered thin films at the nanoscale, but at the expense of uniformity across the substrate.

By performing spin coating at very low speeds, it is possible to obtain the high level of nanoscale order produced by droplet casting in combination with the uniformity of spin coating.

Other concerns in research environments are the need to coat often very small substrates, the desire to use in difficult spaces such as glove boxes, and the desire to keep services (vacuum, compressed air or nitrogen) to a minimum. The ability to handle chlorinated or aggressive solvents while being low maintenance is also beneficial for many applications.

An important consideration for most applications is the thickness of the film produced during spin coating.

Important aspects that may be considered are the method of spin coating used to dispense the solution, static or dynamic.

In static dispensing, the solution is placed on the substrate while it is stationary, and usually the entire substrate is covered with solution before rotation begins. The Spin Coater is then started and should reach the desired speed as quickly as possible.

In dynamic dispensing, the substrate is first rotated and brought to the desired rotational speed before the solution is dispensed into the center of the substrate. Centripetal force then quickly pulls the solution from the middle of the substrate across the entire area before it dries.

Typically, a pipette or pipette of some description is used to dispense a known volume of liquid on a surface.

- 1Application of Spin Coater in preparation of Bi1.5MgNb1.5O7 film

- 2Spin Coater selection and classification: a one-stop guide

- 3Automatic Film Applicator and spin coating spin coater: Key technologies and applications in industrial production

- 4Spin coatings spin coaters: principles, applications, functions and maintenance

- 5Advantages and disadvantages of spin coating process and ideal use

- 6What is spin coating?

- 7Common defects in spin coating of homogenizer

- 8Four key stages of spin coating

- 9What are the common problems of spin coating experiment?