What are the common problems of spin coating experiment?

两步旋涂和边缘/角珠去除

当用粘性或高沸点溶剂(例如三氯苯)以非常低的旋转速度(低于 500 rpm)进行旋涂时,基材中间通常比基材边缘干燥得更快。虽然中间可能会在几秒钟内干燥,但在某些情况下,基材的边缘可能需要几分钟才能干燥。虽然基材的边缘通常设计为不包含任何活性/关键成分,但如果旋涂机停止,则边缘/角珠可能会向中间扩散,从而破坏薄膜质量。

基本上有两种方法可以去除边缘/角珠。第一种也是更优选的方法是使用两步旋转,第一步编程以提供所需的膜厚度和足够的时间使油墨在大部分基材上干燥,第二步以最大转速甩动去除角珠并干燥基材的其余部分。

在大多数情况下,两阶段旋转是去除边缘珠粒以提高旋涂均匀性的更容易且更可取的方法。然而,在某些情况下,第二阶段(高速)旋转是不可取的,例如,如果您想从旋涂机中取出基材,同时它仍然略微湿润以进行进一步处理,例如甲醇清洗、真空干燥甚至在溶剂饱和的气氛中干燥较慢。在这些情况下,可以使用第二种但更精细的技术来去除边缘珠子,其中使用细棉签在其仍在旋转时吸收多余的溶液。

关键是要避免将基板从卡盘上敲下来,也不要损坏基板上的有源区。要通过棉签有效去除角珠,请遵循以下几点:

非常缓慢地接近基材。

将手放在盖子上以稳定手,并使用盖子上的中心孔来稳定并引导棉签进入。

尽量不要触摸实际的基板;将棉签的尖端保持在基材上方的一小部分,使其仅与边缘珠接触,而不与基材接触。

“感觉”棉花棒就像一根占卜棒;即使是轻柔的棉签在基材上的触碰也会产生一种您应该能够感觉到的感觉。

仔细观察棉签;许多有机和纳米技术墨水都是彩色的,因此您应该能够看到棉签何时足够接近以吸收墨水。

尽量让棉签尽可能靠近基材的边缘。

避免在胶片中间出现漏洞

初学者常见的旋涂缺陷是在基板中间看到一个孔,上面没有涂层。

这通常是由于墨水未分配在基材中间造成的。由于向心力总是使油墨流到基材的边缘,中间不会被涂上。通过将墨水分配到更靠近基材的中心,应该可以消除这种情况。请注意,通过使用盖子中心孔的边缘来引导移液器,可以更准确地定位移液器。

避免基板真空翘曲

许多旋涂机使用真空将基材固定到位。这不仅经常会导致旋涂机维护问题(真空通常会试图吸入墨水和溶剂),而且还会使基材轻微翘曲,从而导致均匀性问题。问题的严重程度取决于基板的厚度、真空强度和真空孔的大小。

基板的机械刚度与其厚度的立方成正比,因此 1.1 毫米厚的基板将是等效 0.55 毫米基板的八倍。一般来说,对于厚度小于约 1 毫米的基板,基板翘曲会成为一个问题,并且在低速(向心力较小的情况下)效果更差。

以下几点也将有助于缓解真空翘曲的问题:

使用较厚的基材

使用更高的旋转速度

旋涂前将基板安装在厚载板上

旋涂低粘度溶剂

当旋涂溶剂的粘度会对薄膜质量产生重大影响时。由于历史或其他原因在研究领域中普遍存在的某些溶剂具有非常低的粘度,这可能会带来重大问题。这种溶剂的例子包括氯仿和丙酮,这里有两个主要问题:

溶液在它应该滴出之前从移液管中滴出

在产生均匀的湿层之前薄膜干燥,这会在基材中产生漩涡

关于墨水从移液器中滴出的问题,首先要做的是使用可用的最小尺寸的移液器吸头,因为它的末端直径较小,可以减少滴落。它还有助于吸取涂层所需的最少量墨水,因为与表面张力相比,这将减少重量的影响(10µl溶液的重量是20µl的一半,但表面张力保持不变)。

如果溶剂是卤化的(例如氯仿),那么在取出移液器吸头之前将其留在墨水中几秒钟也有帮助。原因是大多数移液器吸头由聚丙烯制成,聚丙烯不会溶解在卤化溶剂中,但会略微膨胀,这会降低孔径的有效直径。

该技术不适用于丙酮等非卤化溶剂,因为它们不会使聚丙烯溶胀。因此,另一种选择是将移液器倾斜一个角度以降低重量与表面张力的比率,仅在分配溶剂之前将移液器恢复到垂直状态。需要小心不要将移液器倾斜到溶剂进入移液器并损坏移液器的程度。

基材涂层不完全

油墨在基材上的润湿通常以液体在表面上的接触角为特征。低接触角意味着良好的润湿性(油墨喜欢在基材上扩散),而高接触角意味着润湿性差(油墨喜欢起球)。

The contact angle will depend on the surface tension of the liquid and the surface energy of the substrate. Liquids with high surface tension ball up more easily than liquids with low surface tension. At the same time, substrates with high surface energy are more likely to attract ink because it results in an overall lower energy state. Some ink/substrate combinations will paint well with ink that wants to spread across the surface, while in others it will want to ball up. In extreme cases, this can mean that it is impossible to get ink on the surface at all. More commonly, it is difficult to wet the surface, which often results in partial coating of the substrate.

The first and simple solution to this problem is to simply deposit more ink - for example, for a standard 20 x 15 mm substrate, you can increase the dispensing volume on the pipette from 20 to 50 or even 100 µl. Increasing the temperature of the ink and heating or heat distribution also helps reduce the time it takes for the ink to dewet from the surface by reducing surface tension and increasing the rate of evaporation.

However, if the above options do not work, you will usually need to change the solvent in the ink to one with a lower surface tension, or treat the substrate in some way, such as by UV/ozone or oxygen plasma to increase the surface energy ( Note that this is generally not desirable for organic transistors where low surface energy is critical for high performance).

Pinhole Defects and Comet Streaks

Regardless of the application method, the physical and chemical cleanliness of the substrate is of paramount importance for high-quality films. For spin coating, the effects of dust and particulate matter often cause pinholes and comet streaks, but this can also be caused by particles in the ink as described in the following sections.

To remove dust and particulate matter, an electronics-grade cleaner such as Hellmanex III is often recommended. However, it is also important to remove any residue on the surface, as semi-polar solvents such as acetone/IPA will help remove these residues. It is usually worthwhile to chemically prepare the substrate by using alkaline NaOH solution or oxygen plasma/UV ozone prior to applying the first coat to produce the '-OH' terminations which are excellent for most coating processes. Therefore, for most substrates, the following standard cleaning procedures should be used. Where possible, use a solution-based NaOH process to provide "-OH" surface termination for convenience and simplicity, but in the case of silicon, this will damage the surface, so use oxygen plasma treatment instead.

After the substrate is cleaned, store it in a clean environment (usually in deionized water) to avoid dust and other contaminants. This is important because even though the dust can be blown away from the substrate, it often causes a change in the energy of the surface where the dust particles are placed, which can lead to pinholes in the surface.

aggregate and filter

Even during spin coating, it is possible for aggregates or crystallites to form in solution prior to deposition. This can cause comet streaks or chunks to collect on the surface.

Typically, heating and stirring the solution will help dissolve the active material, then cooling and filtering will remove any aggregates and undissolved material, which can often have a significant impact on device performance.

However, for many materials, ink solutions can be unstable and reform aggregates or crystallites over time, such as the following examples of P3HT films, PCBM crystallites, and F8BT aggregates, if the ink is left to stand, All of these build up over long periods of time (hours to days).

In some cases these particles can be redissolved by reheating/stirring, and it is often worthwhile to filter again after the solution has cooled. However, in some cases, such as PCBM, the crystallization energy is large, so it is difficult if not impossible (depending on the solvent) to redissolve them, so a fresh solution should be used each time.

Before filtering any solution, however, it is always worth considering the size of any solute relative to the filter pore size; while polymers, PCBMs, and small nanoparticles (<20 nm or so) can all filter without problem, larger There is a good chance that the particles or graphene flakes are captured by the filter and completely removed from the solution (leaving only the solvent).

- 1Application of Spin Coater in preparation of Bi1.5MgNb1.5O7 film

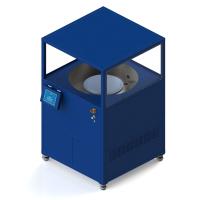

- 2Spin Coater selection and classification: a one-stop guide

- 3Automatic Film Applicator and spin coating spin coater: Key technologies and applications in industrial production

- 4Spin coatings spin coaters: principles, applications, functions and maintenance

- 5Advantages and disadvantages of spin coating process and ideal use

- 6What is spin coating?

- 7Common defects in spin coating of homogenizer

- 8Four key stages of spin coating

- 9Spin-on cleaning and specific cleaning steps