Why measure gloss?

Gloss is an aspect of the visual perception of an object that is as important as color when considering the psychological impact of a product on consumers.

It is defined as "the surface property that gives them a shiny or lustrous metallic appearance".

The glossiness of a surface can be greatly influenced by many factors such as the smoothness achieved during polishing, the amount and type of coating applied or the quality of the substrate.

Manufacturers design their products to be attractive – highly reflective body panels, glossy magazine covers or satin black designer furniture.

Therefore, it is important to achieve a consistent level of gloss on each product or from batch to batch.

Gloss can also be a measure of surface quality, for example, a decrease in gloss on a coated surface could indicate a problem with its curing, leading to other failures such as poor adhesion or a lack of protection on the coated surface.

It is for these reasons that many manufacturing industries monitor the gloss of their products, from automotive, printing and furniture to food, pharmaceuticals and consumer electronics.

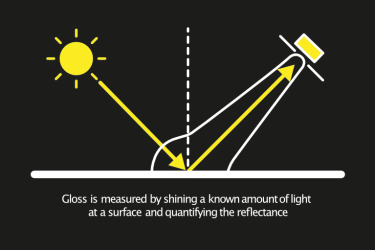

A gloss meter (also known as a gloss meter) is an instrument used to measure the specular reflection (glossiness) of a surface. Gloss is determined by projecting a beam of light onto a surface at a fixed intensity and angle and measuring the amount of reflected light at an equal but opposite angle.

There are many different geometries that can be used for gloss measurement, each depending on the type of surface being measured.

For non-metals, such as coatings and plastics, the amount of reflected light increases with the angle of illumination because some of the light penetrates the surface material and is absorbed into it, or is diffusely scattered from the surface material depending on its color. Metals are more reflective and therefore less angularly dependent.

There are a number of international technical standards available which define the use and specifications of different types of gloss meters for various materials including paints, ceramics, paper, metals and plastics.

Many industries use gloss meters in quality control to measure the gloss of products to ensure consistency in their manufacturing processes. The automotive industry is a major user of gloss meters, with applications extending from the factory floor to the repair shop.

- 1Principle and Application of Glossiness Tester

- 2Working Principle and Application of Metal Gloss Meter

- 3Basic principle and application analysis of insulating paint gloss Detector

- 4Working principle and application analysis of film Glossmeter

- 5Principle and application analysis of microporous gloss meter

- 6 FZ/T 01097 Analysis of fabric gloss test method

- 7Evaluation and Application of Optical Properties of Powder coatings

- 8Coating coatings - Determination of surface gloss and Gloss meter

- 9The Importance and Method of Gloss Measurement of Paint Film