Gloss Meter - Coating Inspection Instrument Guide

Gloss Meter Guide: From Matt to Gloss

The sheen of a surface doesn't just tell us how smooth it is. Surface properties reveal issues such as cure failures, surface preparation issues, or inconsistent film formation. Furthermore, the gloss of a surface is almost as important as the color when it comes to consumer choice – inconsistencies between products will be attributed to poor quality or defects, neither of which will lead them to purchase. In fact, a glossy product adds to the impression of value, and it goes without saying how important quality control measures such as gloss meters are to monitoring and maintaining the high performance of a coating or surface. Many industries and applications have quantitative gloss requirements to ensure standards are set.

Detecting Reflection – What a Gloss Meter Measures

The term "gloss" refers to the impression of a surface's glossiness - the more light a surface reflects, the more glossy it is. Highly polished, smooth surfaces reflect incident light directly so reflected images appear sharp; think of reflections in mirrors or spoons. Both are high-gloss surfaces, but the angle of the spoon changes the angle of reflection, which distorts the image without losing clarity. Matte or semi-gloss surfaces diffuse light, scattering it in all directions from uneven surfaces. As a result, surfaces appear dull and flat, with blurred reflections.

A gloss meter measures the intensity of reflected light bouncing off a surface. In order for this measurement to be meaningful across industries and machines, several standards are used. The light source is standardized and the reflective surface on which it is calibrated is highly polished flat black glass. This criterion is assigned a value of 100 Gloss Units (GU) across angles. Intensity depends on material and lighting angle. Non-metals reflect more light at higher illumination angles, while metals are reflective at any angle and can yield measurements up to 2000GU.

How Gloss Meters Work - What the Measurements Mean

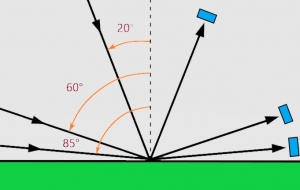

Making meaningful measurements means understanding the processes involved in producing the final numbers. Measuring from the wrong angle can lead to erroneous and unhelpful results. First, you need to determine whether the surface you are testing is glossy, semi-gloss, or matte, and what type of material it is. The angle of the incident light was chosen based on the expected glossiness of the surface - use 20° for high gloss, 60° for semi-gloss and 85° for matte.

20° Range: The 20° geometry has a measurement range of 0 to 2000GU. It is the widest range as it is used for measuring high gloss surfaces. This angle is sensitive to effects such as smog.

60° Range: All gloss levels can be measured with the 60° geometry and used as a reference angle. It has a value from 0 to 1000GU, the reason higher or lower angles are chosen is because they give more accurate results for both high gloss and matte surfaces - a reading of 70GU at 60° means it can be measured from 20°, while 10GU A result of 85° or less will result in the 85° measurement being used. 60° is especially suitable for semi-gloss.

85° Range: This is the range for accurate readings on matte and low gloss surfaces. It provides a larger measurement area and can eliminate differences provided by surface texture.

45° and 75° ranges: for ceramic/film and paper/vinyl industries respectively. The gloss unit value returned by the measurement is usually converted to a percentage. For example, a 1000GU rating at 20° is 50% of its 0-2000GU range, but will be 100% of its 60° range. The higher the percentage, the brighter the surface.

- 1Gloss inspection method of slurry inks

- 2Principle and Application of Glossiness Tester

- 3Working Principle and Application of Metal Gloss Meter

- 4Basic principle and application analysis of insulating paint gloss Detector

- 5Working principle and application analysis of film Glossmeter

- 6Principle and application analysis of microporous gloss meter

- 7 FZ/T 01097 Analysis of fabric gloss test method

- 8Evaluation and Application of Optical Properties of Powder coatings

- 9Coating coatings - Determination of surface gloss and Gloss meter