How to measure glossiness?

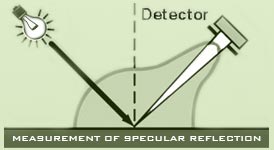

Glossiness is measured by shining a known amount of light on a surface and quantifying the reflectance. The angle of light and the method of measurement reflectance are determined by the surface.

Glossiness is measured using a Glossiness Meter (also known as a Glossiness Meter), which guides light to the test surface at a specific angle while measuring reflection. The type of surface to be measured determines the Glossiness Meter angle to be used, which determines the model of the Glossiness Meter.

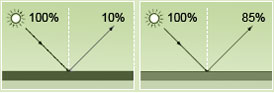

Intensity depends on the material and the illumination angle. In the case of non-metals (coating, plastic), the amount of reflected light increases with the illumination angle. The remaining illumination light penetrates the material and is absorbed or diffusely scattered according to Color.

Metal

Metals have a higher reflectance and are less dependent on angle than non-metals. The measurement result of the Glossiness Meter is related to the amount of reflected light from the Black Glass standard with a specified refractive index, independent of the incident ray amount. The measurement value of this defined standard is equal to 100 gloss units. Materials with a higher refractive index can have measurements above 100 gloss units (GU), such as thin films.

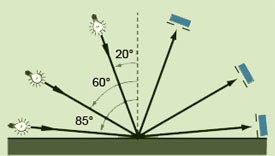

In the case of transparent materials, measurements may increase due to multiple reflections in the body of the material. Values up to 2000 GU can be reached due to the high reflection capacity of the metal. For these applications, measurement results are usually recorded as a reflection percentage of the illuminated light. Glossiness meters and their handling procedures must be specified internationally to allow comparison of measurement values. The effect of the lighting angle is large. To achieve a clear distinction over the entire measuring range from high gloss to matte, 3 different geometries are defined using a 60 ° Glossiness Meter, i.e. 3 different ranges.

- 1Principle and Application of Glossiness Tester

- 2Working Principle and Application of Metal Gloss Meter

- 3Basic principle and application analysis of insulating paint gloss Detector

- 4Working principle and application analysis of film Glossmeter

- 5Principle and application analysis of microporous gloss meter

- 6 FZ/T 01097 Analysis of fabric gloss test method

- 7Evaluation and Application of Optical Properties of Powder coatings

- 8Coating coatings - Determination of surface gloss and Gloss meter

- 9The Importance and Method of Gloss Measurement of Paint Film