What are the measurement requirements for a Leeb Hardness Tester?

Abstract:

这篇文章概述了使用里氏硬度计进行测量的要求。首先,试样表面应光滑无污垢,表面粗糙度需符合规定。试样需要足够的质量和刚度,以防止测试时的位移或反弹。试样的最小厚度应达到标准要求。此外,如果试样表面有硬化层,其深度也需符合规定。对于各种形状的试样(如凹面、凸面、圆柱形和球形),表面曲率半径需满足标准要求,并应使用适当的支撑环以确保测试精度。试样不应具有磁性。每个测量点之间的距离应大于3~4mm,以避免在同一点重复测试,从而减少误差并延长传感器的使用寿命。

1. Requirements for the surface of the sample

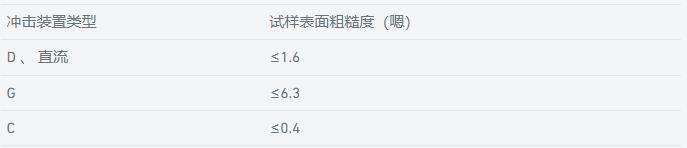

The test surface should have metallic luster, no scale and other dirt, and the surface roughness should meet the following requirements:

2. Sample weight requirements

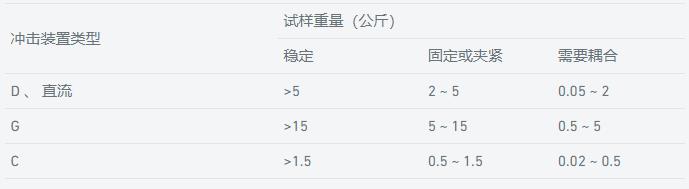

Specimens need to be of sufficient mass and stiffness to ensure no displacement or rebound during reconstruction. Quality should meet the following requirements:

3. Sample thickness requirements

The sample should have sufficient thickness, and the minimum thickness should meet the following requirements:

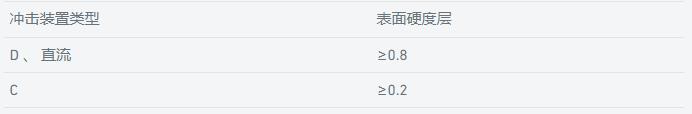

4. There is a hardened layer on the surface of the sample, and the depth of the hardened layer should meet the following requirements:

5. For concave, convex, cylindrical and spherical samples, the surface curvature radius should meet the following requirements:

For specimens with curved surfaces, appropriate support rings should be used to ensure that the position deviation of the impact head is within 0.5mm during impact.

6. The sample should not be magnetic.

7. The distance between each measurement point should be greater than 3~4mm, and the test cannot be repeated at the same point, otherwise it will cause a large error. At the same time, the service life of the sensor will be shortened.

Products required

-

Leeb Hardness Tester DHT-400Dplus$ 1938.00

-

-

-

Leeb Hardness Tester DHT-100Dplus$ 1312.00

-

-

-

-

-

Relevant knowledge

- 1Read the Leeb Hardness Tester in one article

- 2Leeb Hardness Tester different hardness system difference

- 3What products is the Leeb Hardness Tester with D probe suitable for measuring?

- 4Factors Affecting the Accuracy of Leeb Hardness Tester Testing

- 5Leeb Hardness Tester measurement requirements

- 6Factors Affecting the Test Accuracy of Leeb Hardness Tester

- 7What factors affect the test accuracy, error and repeatability of the Leeb Hardness Tester?

- 8What is hardness testing? What types are there?

- 9Requirements for Casting Hardness in American Standard ASTM and Selection of Sclerometer

Guess you like it

-

-

PRLH150 Leeb Hardness Tester$ 259.00

-

-

-

-