New technology for automobile painting construction-----paint blending technology

Paint blending technology: automotive paint can be divided into primer blending, intermediate paint blending, top coat blending, color paint blending and varnish blending.

Paint blending technology: automotive paint can be divided into primer blending, intermediate paint blending, top coat blending, color paint blending and varnish blending.

1. Primer blending method

For the formulation of the primer, since the primer contains anti-rust pigments (such as Qianhong, etc.) and extender pigments, it is easy to precipitate, especially for various primers that have been stored for a long time, the precipitation is often serious, that is, the pigment slurry settles at the bottom of the barrel. The upper part is the paint. If it is not stirred evenly, it will not only affect the hiding power and anti-rust performance of the coating, but also the pigment slurry deposited at the bottom of the bucket will become hard lumps due to lack of paint wetting, resulting in waste and reduced usage.

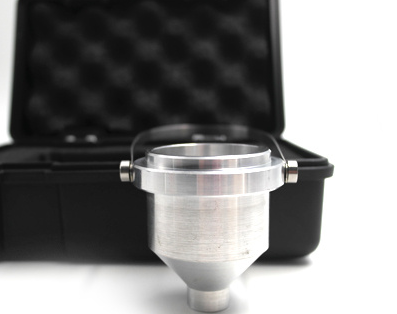

When blending the primer, an appropriate blending method should be adopted according to the type and performance of the primer so as to facilitate the construction, improve the quality of the paint and improve the utilization rate of the paint. For example, iron red phenolic antirust paint is mainly used for dipping ( dipping . It should be diluted to a suitable viscosity according to the construction method. Usually, the dipping viscosity is 14~18 (average Take Tu-4 viscometer as an example), the brushing viscosity is 30~40 seconds. During the deployment, first open the lid of the original bucket paint, stir it evenly with a wooden stick, etc., then dilute the dipping coating, add 35-40 kg of alkyd thinner for every 100 kg of the original bucket paint, stir well, and then you can Make the viscosity approximately !# $ !% seconds; such as brush coating, add about )'* thinner for every !' kg of the original paint bucket, and the viscosity can be approximately 14~18 seconds after stirring. In order to shorten the paint stirring time, for the use of batches of primer (such as dipping, etc.), the paint bucket used can be turned upside down (bottom up) a few days in advance, so that the pigment slurry at the bottom can be moved to the upper part of the bucket, so that when used The mixing time can be greatly shortened.

For the sprayed iron red alkyd primer, after effective stirring, it is generally necessary to add (40~50% thinner according to the weight of the original bucket paint) to make the viscosity reach the spraying construction viscosity of 18~22 seconds. It needs to be filtered with 80-100 mesh sieve before spraying.

For nitro or perchlorethylene primers, it is usually necessary to add more thinner to dilute to achieve the spraying viscosity. Such as nitro-based primer, generally according to the weight of the paint and thinner 1:1 or 1:1-1:2 thinner, the viscosity can easily reach 18~22 seconds. The perchlorethylene primer should also be thinned by adding 50-60% thinner according to the weight of the paint, so as to approach the viscosity of spraying.

2. Intermediate layer paint blending method

The intermediate paint mainly refers to the surfacer (surfacer) and intermediate paint. The surfacer paint contains a lot of extender pigments, which are easy to precipitate. Therefore, when mixing, the lid of the barrel should be completely removed or half removed to facilitate effective stirring.

For the thinning of the surfacer, different proportions are used according to the type of paint used. Such as alkyd, phenolic and ester glue surfacer, generally can add about 30~40% thinner according to the weight of the paint, after fully stirring, the viscosity can be close to 18~22 seconds construction viscosity. But the secondary paste is diluted Finally, filter with a 50% mesh sieve to ensure that the paint is clean. For amino drying secondary slurry, it is usually necessary to add about 60~70% thinner to approach the construction viscosity; for perchlorethylene secondary slurry, it is necessary to add 1.2~1.5 thinner; for nitro secondary slurry, it is necessary to add 1.2 ~1.5 times the weight of the thinner, it is easy to reach the construction viscosity.

For the deployment of center paint, since the paint contains less extender pigment than the surfacer, and the resin (paint) content is more than that of the primer, the sedimentation of the pigment paste is lighter than that of the primer. The primer is easy to stir evenly, and the amount of thinner is generally about 50% of the weight of the paint (referring to the amino paint). After diluting and mixing thoroughly, filter it with a 180-mesh sieve, and then spray it. In the case of nitro-based paint, more than 1 times the thinner should be added to dilute.

3. Topcoat blending method

Most of the topcoats currently used in automobiles, especially those used in cars, are matching topcoats. For example, in the use of topcoats, domestic automobile manufacturers first select the topcoat color suitable for this type of car according to the national standard Color Chart or the product Color Chart of the paint factory, and then produce it according to this color by the paint factory. supply. There are special matching topcoats for various imported cars. When repairing or repairing paint, you only need to purchase paint and spray according to the specified color paint number of the car. Therefore, all kinds of topcoats currently used in automobiles are matching topcoats. When using them, you only need to add a certain proportion of matching thinners to dilute them, filter and clean them, and then spray them. Generally, there is no need for color matching, which greatly facilitates the topcoat coating.

Topcoats contain only coloring pigments without extender pigments (fillers) and have a high resin content (compared to primers). Due to the large amount of resin, it has good floatability for pigments and is not easy to precipitate. It is easy to stir evenly when using it. After stirring evenly, add thinner to adjust to the construction viscosity, and filter it clean.

The thinner of the topcoat should be adjusted according to the type of topcoat, such as nitro enamel, the thinner used is usually 1.2~1.5 times the weight of the paint, the thinner used for perchlorethylene enamel thinning is 50~70%, alkyd The amount of thinner for enamel paint is 20-30%, about 35-45% for amino baking varnish, and about 30% for two-component polyurethane enamel.

Generally speaking, the construction viscosity of the front topcoat is 18~22 seconds, and the construction viscosity of the final topcoat is 16~20 seconds (coating - 4 cups of viscometer). That is, the application viscosity of the final topcoat should be appropriately lower (thinner), so that after the final topcoat is sprayed, the smoothness of the film will be good after drying, and orange streaks will not easily occur. In addition, the thinning viscosity should be determined according to the factors of temperature, such as summer construction, the viscosity should be adjusted lower; and winter construction, the viscosity should be adjusted appropriately higher. Make the painted topcoat not only have good hiding ability (covering the bottom), but also have good smoothness, brightness and fullness.

After the various topcoats are diluted, they need to be filtered with a 180~240 mesh fine screen before spraying to ensure the quality of . In terms of topcoat thinners, it is necessary to use supporting thinners or special thinners, and do not use them indiscriminately, so as not to affect the quality of dilution or cause gelation accidents.

For the deployment of two-component topcoats, it is necessary to prepare them as they are used, as much as they are used, and the prepared paint should be used up within a few hours or within the time specified by the product to avoid waste.

4. Paint blending method

Color paint mainly refers to the color strip paint on the exterior of various long-distance buses, city traffic buses and trams. For the deployment of this kind of paint, in addition to using the finished color paint matched with the color strip of the car, the painter often needs to prepare it by himself. Before blending, two or more paints should be blended according to the color of the color bar. When blending, the main color should be added first and then the secondary color. When adjusting, it should be done less and more times to prevent the color from being overdone (too heavy). If you mix fuchsia, you should increase , and then add a small amount of dark blue and black several times. When mixing sky blue, white should be added first, and then blue should be gradually added. In order to ensure the accuracy of color matching, a small sample should be prepared according to the standard color plate or the color bar color on the car. After the small sample is registered, the large sample (dosage) should be prepared according to this ratio, so as to avoid excessive color. After the color is adjusted, add a certain amount of thinner for thinning. After the thinning, a color comparison should be carried out to confirm that it is correct, and then filter and spray.

5. Varnish blending method

The varnishes used in automotive finishing are mainly amino drying varnishes, acrylic varnishes and two-component polyurethane varnishes. It is mainly used for surface finishing of metallic flash paint and aluminum powder paint. The general topcoat usually does not need to be varnished, and it has a better gloss.

When formulating amino drying varnish, add about 40% amino thinner according to the weight of the paint, stir well, and filter with 280 mesh screen before spraying. However, for the amino color baking enamel, if you want to improve the surface gloss sometimes, you can add 30~40% or 40%~50% amino clear baking varnish to the color enamel before spraying the final top coat, and stir well And dilute to the construction viscosity, filter and spray wet-on-wet twice, can greatly improve the gloss, no need to use varnish separately. This maintains the vibrancy of the topcoat color while enhancing the gloss. If varnish is used alone for varnishing, for light-colored topcoats, especially white topcoats, when varnishes are sprayed overlapping (such as lap joints, etc.), the color of the vehicle's topcoat is prone to color difference.

However, for metal flash paint or aluminum powder paint, it needs to be finished with varnish alone. The type of varnish should be polyurethane or acrylic is recommended not to finish with amino or other varnishes to prevent color difference in the color depth of the varnish. When preparing polyurethane varnish, usually by weight 4 parts of varnish, 2 parts of thinner, and 1 part of curing agent (ie 4:2:1), stir well and use immediately after filtering. For the deployment of acrylic varnish, if it is a one-component, thinner can be directly added for dilution, while for two-component acrylic varnish, it should be prepared according to the ratio specified by the product.

- 1Viscosity of polypropylene (PP) amide measured by NDJ Viscometer

- 2Overview of resistant coatings

- 3Characteristics and construction points of corrosion resistant Coatings

- 4Application of corrosion resistant coatings on reinforced concrete surfaces

- 5Technological development and application of heavy anticorrosive coatings

- 6Application and performance analysis of silicon diffusion coatings

- 7Research and application of chromium diffusion coatings

- 8High temperature oxidation and corrosion resistance performance and application of aluminum diffusion coatings

- 9Zinc diffusion coating performance process and application